1

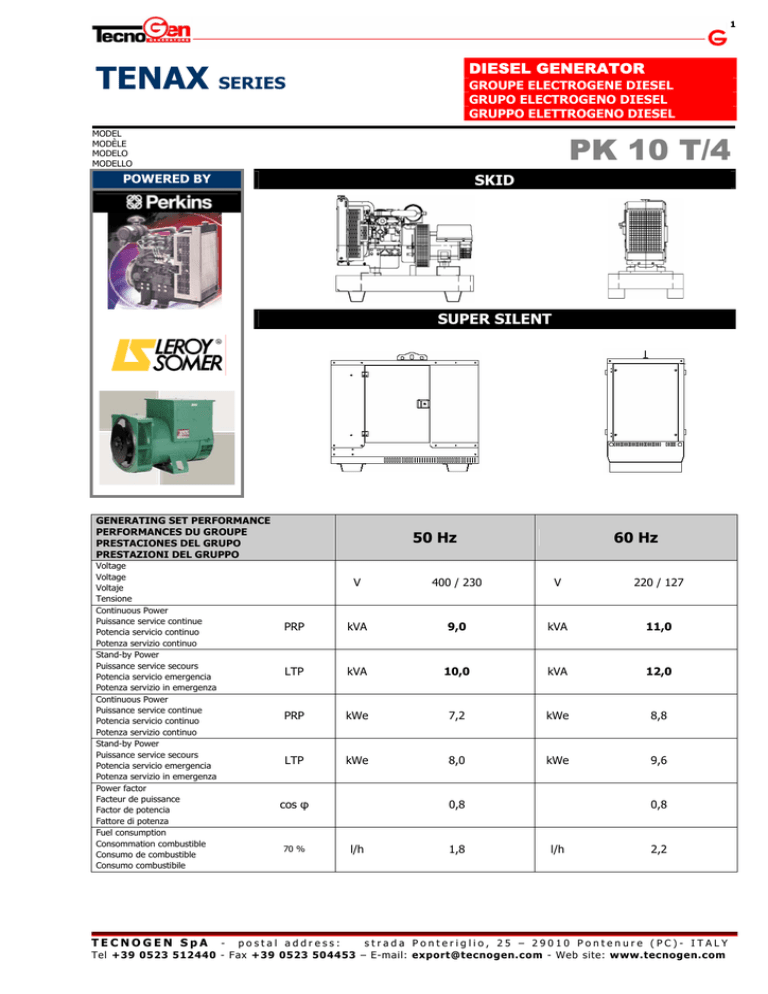

DIESEL GENERATOR

TENAX SERIES

GROUPE ELECTROGENE DIESEL

GRUPO ELECTROGENO DIESEL

GRUPPO ELETTROGENO DIESEL

MODEL

MODÈLE

MODELO

MODELLO

PK 10 T/4

POWERED BY

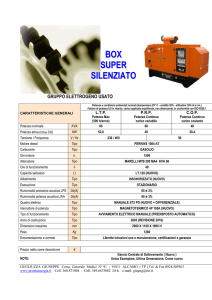

SKID

SUPER SILENT

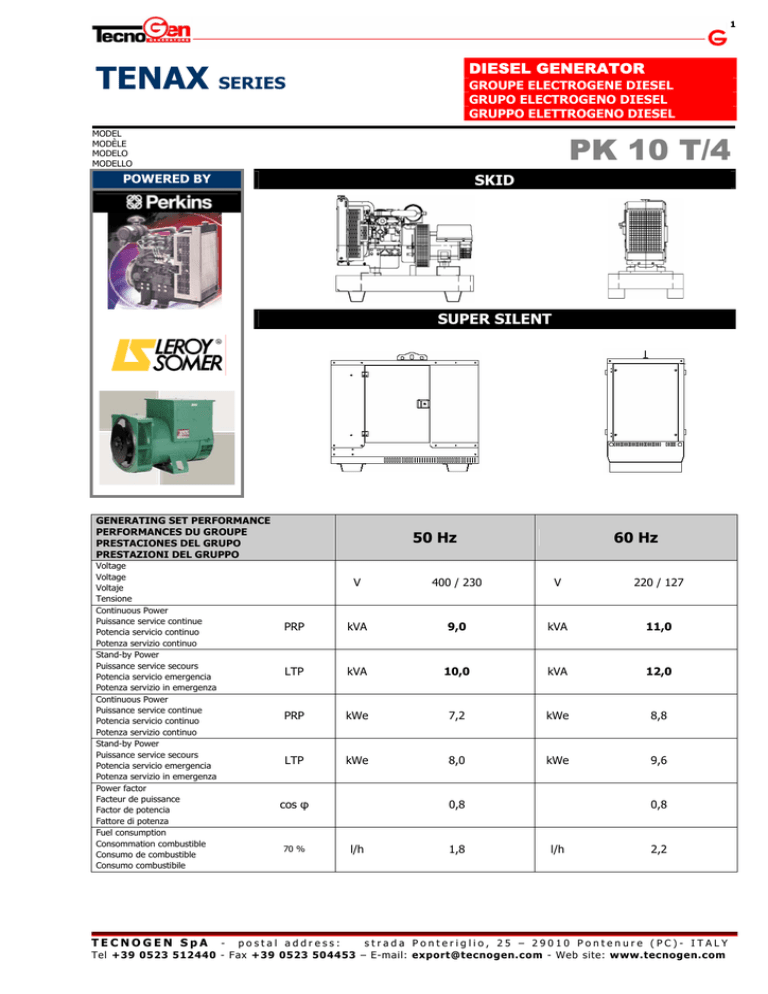

GENERATING SET PERFORMANCE

PERFORMANCES DU GROUPE

PRESTACIONES DEL GRUPO

PRESTAZIONI DEL GRUPPO

Voltage

Voltage

Voltaje

Tensione

Continuous Power

Puissance service continue

Potencia servicio continuo

Potenza servizio continuo

Stand-by Power

Puissance service secours

Potencia servicio emergencia

Potenza servizio in emergenza

Continuous Power

Puissance service continue

Potencia servicio continuo

Potenza servizio continuo

Stand-by Power

Puissance service secours

Potencia servicio emergencia

Potenza servizio in emergenza

Power factor

Facteur de puissance

Factor de potencia

Fattore di potenza

Fuel consumption

Consommation combustible

Consumo de combustible

Consumo combustibile

TECNOGEN SpA

50 Hz

60 Hz

V

400 / 230

V

220 / 127

PRP

kVA

9,0

kVA

11,0

LTP

kVA

10,0

kVA

12,0

PRP

kWe

7,2

kWe

8,8

LTP

kWe

8,0

kWe

9,6

cos φ

70 %

0,8

l/h

1,8

0,8

l/h

2,2

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

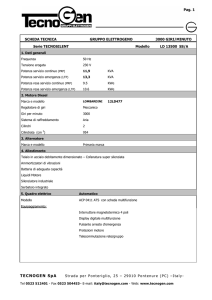

2

ENGINE

MOTEUR

MOTOR

MOTORE

PERFORMANCE

PERFORMANCES

PRESTACIONES

PRESTAZIONI

PERKINS

403D-11G

1500 rpm

1800 rpm

Continuous Power

Puissance service continue

Potencia servicio continuo

Potenza servizio continuo

PRP

kWm

8,4

kWm

10,3

Stand-by Power

Puissance service secours

Potencia servicio emergencia

Potenza servizio in emergenza

LTP

kWm

9,3

kWm

11,4

Specific fuel consumption

Consommation spécifique combustible

Consumo especifico de combustibile

Consumo specifico combustibile

Diesel

Diesel

Diesel

Diesel

g/kWh

50

75

100

110

%

%

%

%

280

257

248

268

50

75

100

110

g/kWh

280

257

248

268

%

%

%

%

Indirect

Indirecte

Indirecta

Indiretta

4 Stroke – Injection type

4 temps – Type injection

4 tiempos – Tipo de inyeccion

a 4 tempi – Tipo di iniezione

Aspiration type

Type d’aspiration

Tipo de aspiracion

Tipo d’aspirazione

Natural

Naturel

Natural

Naturale

Cooling system

Refroidissement

Sistema de refrigeracion

Raffreddamento

Water

Eau

Agua

Acqua

Speed governor

Régulateur de tours

Regulador

Regolatore di giri

Mechanical

Mécanique

Mecanico

Meccanico

Cylinders, numbers and arrangement

Nombre et disposition des cylindres

Cilindros, numero y disposicion

Numero e disposizione dei cilindri

3L

Total displacement

Cylindrée totale

Cilindrata total

Cilindrata totale

Bore x stroke

Alésage x course

Diametro x carrera

Alesaggio x corsa

cm3

mm

1.131

77.0 x 81.0

Compression ratio

Rapport de compression

Relación de compresión

Rapporto di compressione

23.0:1

Engine electric system voltage

Voltage système électrique moteur

Voltaje sistema eléctrico motor

Voltaggio sistema elettrico motore

12 V

Derating for temperature

Déclassement pour temperature

Declasamiento para temperatura

Declassamento per temperatura

Derating for altitude

Déclassement pour altitude

Declasamiento para altitud

Declassamento per altitudine

Derating for relative humidity

Déclassement pour humidité relative

Declasamiento para humedad relativa

Declassamento per umidità relativa

TECNOGEN SpA

0 ÷ 27°C

0

> 27 °C

0,75 % / 5°C

0 ÷ 500 m

0

500 ÷ 1500 m

3,5 % / 500 m

1500 ÷3000 m

6,5 % / 500 m

30°C & 50% RH

0

30°C&>RH 50%

0,45 %/ 10% RH

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

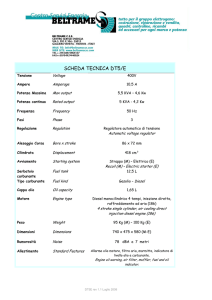

3

ALTERNATOR

ALTERNATEUR

ALTERNADOR

ALTERNATORE

PERFORMANCE

PERFORMANCES

PRESTACIONES

PRESTAZIONI

Model

Modèle

Modelo

Modello

Continuous Power

Puissance service continue

Potencia servicio continuo

Potenza servizio continuo

LEROY SOMER

1500 rpm

1800 rpm

LSA 37 M7

40 °C

Stand-by Power

Puissance service secours

Potencia servicio emergencia

Potenza servizio in emergenza

40 °C

Stand-by Power

Puissance service secours

Potencia servicio emergencia

Potenza servizio in emergenza

27 °C

LSA 37 M7

kVA

13,0

KVA

16,0

kWe

10,4

kWe

12,8

KVA

14,0

KVA

17,0

kWe

11,2

kWe

13,6

KVA

14,5

KVA

17,5

kWe

11,6

kWe

14,0

1/4

Efficiency

2/4

Rendement

3/4

Eficienza

4/4

Efficienza

Standard winding connections

Liaison des bobinages

Tipo de conexiòn

Collegamento avvolgimenti

brushless rotating exciter design with solid state

Exciter

pivotante sans brosses avec pont de diodes pivotants

Eccitatrice

puente de diodos sin escobillas rotantes

Excitador

rotante senza spazzole con ponte di diodi rotanti

Eccitatrice

Poles

Poles

Polos

Poli

Phases

Phases

Fases

Fasi

Wires

Fils

Hilos

Morsetti

Voltage regulation

Regulation Voltage

Regulación voltaje

Regolazione tensione

Waveform distortion

Taux d’harmonique

Distorciòn forma de onda

Distorsione forma d’onda

Insulation class

Classe d’ isolation

Classe de aislamiento

Classe di isolamento

Enclosure

Degré de protection mécanique

Grado de protecciòn mecanica

Grado di protezione meccanica

Maximun overspeed

Survitesse

Régimen màximo

Velocità di fuga

Standard AVR model

Modèle AVR standard

Modelo AVR standard

Modello AVR standard

81,8

86,0

86,3

85,5

%

%

%

%

82,0

86,6

87,2

86,6

1/4

2/4

3/4

4/4

Y

%

%

%

%

YY

4

3+N

12

± 0,5 %

IEC

< 2%

H

IP 23

2250 min

R 250

shunt

Derating for temperature

Déclassement pour temperature

Declasamiento para temperatura

Declassamento per temperatura

0 ÷ 40°C

0

> 40 °C

3 % / 5°C

Derating for altitude

Déclassement pour altitude

Declasamiento para altitud

Declassamento per altitudine

0 ÷ 1500 m

TECNOGEN SpA

0

1500 ÷ 2500 m

3% / 500 m

2500 ÷ 3000 m

4% / 500 m

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

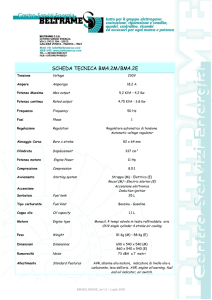

4

LOGISTIC INFORMATION

INFORMATIONS LOGISTIQUES

INFORMATION LOGISTICA

INFORMAZIONI LOGISTICHE

Integrated fuel tank capacity

Capacité reservoir intergré

Capacidad Tanque integrado

Capacità Serbatoio integrato

STANDARD

Weight

Poids

Peso

Peso

EXTRA 1

EXTRA2

(L)

OPEN SKID VERSION

VERSION SUR SKID

VERSION ABIERTA

VERSIONE APERTA

SOUND PROOF VERSION

VERSION INSONORISEE

VERSION INSONORISADA

VERSIONE INSONORIZZATA

Dimensions

Cotes d’encombrement

Medidas externas

Dimensioni d’ingombro

(kg)

L

(cm)

W

H

50

108

166

335

117

73

105

50

100

ON REQUEST

460

175

76

117

GENSET STANDARD EQUIPMENT

EQUIPEMENT STANDARD GROUPE ELECTROGENE

EQUIPAMIENTO STANDARD GRUPO ELECTROGENO

EQUIPAGGIAMENTO STANDARD GRUPPO ELETTROGENO

GB

F

•

•

•

•

•

•

Heavy duty steel base frame

Vibration dampers

Integrated fuel tank

Silencer industrial type

Battery

Manual control panel

model MCP 120-14

• Key start switch

• Emergency stop button

• Sound proof canopy of

galvanized

steel

with

residential

silencer

for

Super Silent version

•

•

•

•

•

•

Châssis acier

Amortisseurs de vibrations

Réservoir intégré

Silencieux industriel

Batterie

Coffret de contrôle manuel

MCP 120-14

• Clé de démarrage

• Bouton arrêt d’émergence

• Capote d’insonorisation d’acier

galvanisé

avec

silencieux

résidentiel pour la version

Super Silent

E

•

•

•

•

•

•

Telar de acero

Apagadores de vibracion

Tanque combustible

Silenciador industrial

Bateria

Cuadro electrico manual MCP

120-14

• Llave par arranque

• Botón parada de emergencia

• Cabina de insonorización de

acero cincado con silenciador

residencial por la versión

Super Silent

I

•

•

•

•

•

•

•

Basamento in acciaio

Antivibranti

Serbatoio integrato

Silenziatore industriale

Batteria avviamento

Chiave avviamento

Quadro elettrico manuale

MCP 120-14

• Pulsante arresto di emergenza

• Cabina di insonorizzazione di

acciaio zincato con marmitta

residenziale per la versione

Super Silent

MANUAL CONTROL PANEL

COFFRET ELECTRIQUE MANUEL

CUADRO ELECTRICO MANUAL

QUADRO ELETTRICO MANUALE

MCP 120 - 14

13 A (400 V - 3 ph - 50Hz – 1500 rpm)

30 A (220 V - 3 ph - 60Hz – 1800 rpm)

STANDARD EQUIPMENT:

4 poles circuit breaker

Electronic control board SPG 120

Key start switch

Control panel box key

Sockets: 1 CEE 2P+T 16A

1 CEE 3P+N+T 16A

Emergency Stop button

SPG

PROTECTIONS

EQUIPEMENT STANDARD:

Disjoncteur de protection 4 pôles

Fiche électronique SPG 120

Interrupteur de démarrage à clé

Clé pour serrure du coffret

douilles: 1 CEE 2P+T 16A

1 CEE 3P+N+T 16A

Interrupteur d’arrêt d’émergence

EQUIPAMIENTO STANDARD:

Interruptor magnetotermico 4 polos

Carta electronica SPG 120

Llave de arranque

Llave cuadro

Zòcalos: 1 CEE 2P+T 16A

1 CEE 3P+N+T 16A

Botón de parada de emergencia

CONTROL BOARD

CARTE ELECTRONIQUE DE CONTROL

120

CARTA ELECTRONICA DE CONTROL

SCHEDA ELETTRONICA DI CONTROLLO

PROTECTIONS

PROTECCIONES

EQUIPAGGIAMENTO STANDARD:

Interruttore magnetotermico 4 poli

Scheda elettronica SPG 120

Interruttore di avviamento a chiave

Chiave quadro

Prese 1 CEE 2P+T 16A

1 CEE 3P+N+T 16A

Pulsante di arresto di emergenza

PROTEZIONI

Low oil pressure

Low fuel level

Overload

Over/Under frequency

Low voltage

Over/Under battery voltage

Belt breakage

Basse pression huile

Bas niveau carburant

Surcharge

Sur/sous fréquence

Bas voltage

Sur/sous voltage batterie

Rupture de la courroie

Baja presión de aceite

Bajo nivel combustibile

Sobrecarga

Sobre/bajo frecuencia

Bajo voltaje

Sobre/bajo voltaje bateria

Ruptura correa

Bassa pressione olio

Basso livello carburante

Sovraccarico

Sovra/sotto frequenza

Basso voltaggio

Sovra/sotto voltaggio batterie

Rottura cinghia

DIGITAL METERS

VOYANT NUMERIQUE POUR

VISOR DIGITAL PARA

MISURATORE DIGITALE PER

Voltmeter

Ammeter (3 phases)

Frequency meter

Hour-meter

Battery voltage meter

Fuel level

Volts

Ampères (3 phases)

Fréquence

Heures

Voltage batterie

Niveau carburant

Voltios

Amperios (3 fases)

Frecuencia

Horas

Voltaje bateria

Nivel carburante

Volt

Ampere (3 fasi)

Frequenza

Ore

Voltaggio batterie

Livello carburante

INDICATORS

INDICATEURS

INDICADORES

INDICATORI

Indicator for periodic maintenance

Light indicator for oil and battery

Light indicator for protection ON

Indicateur pour entretien périodique

Indicateur lumineux huile et batterie

Indicateur lumineux de protection

Indicador de manutención periódica

Indicador luminoso aceite y bateria

Indicador luminoso proteción

Indicatore di manutenzione periodica

Indicatore luminoso per olio e batteria

Indicatore luminoso di protezione

TECNOGEN SpA

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

5

AUTOMATIC CONTROL PANEL

COFFRET ELECTRIQUE AUTOMATIQUE

CUADRO ELECTRICO AUTOMATICO

QUADRO ELETTRICO AUTOMATICO

COMPLETE CONTROL PANEL FREE STANDING TYPE

Equipment: control unit, frequency and voltage indicators, genset/mains supply

contanctors, automatic battery charger.

COFFRET ELECTRIQUE COMPLET TYPE ARMOIRE SEPARE DU GROUPE

Equipement : unité de contrôle, indicateurs fréquence et tension, inverseur de

source, chargeur de batterie automatique.

ACP 0411 ATS

CUADRO ELECTRICO COMPLETO EN ARMARIO SEPARADO DEL GRUPO

Equipamiento: ficha de control, indicadores frecuencia y tensión, contactores

grupo/red, cargador de batería automático.

QUADRO ELETTRICO COMPLETO SEPARATO DAL GRUPPO

Equipaggiamento: unità di controllo, indicatori di frequenza e tensione,

contattori gruppo/rete, carica batteria automatico.

CONTROL BOARD

CARTE ELECTRONIQUE DE CONTROL

CARTA ELECTRONICA DE CONTROL

SCHEDA ELETTRONICA DI CONTROLLO

0411

GB

F

With a generating set wired to

ACP 0411 ATS control panel, the

power

can

be

switched

automatically

to

electrical

services within few seconds (1520) after activation of the signal

indicating a cut in the mains

supply.

MAIN PERFORMANCES

• 4 impulses automatic start

• Immediate or delayed start

after mains failure

• Genset

unit

automatic

anomaly surveillance

• Weekly autotest

• Immediate or delayed stop

after mains voltage return

• Engine protections

• Current

and

voltage

controlled battery recharging

• Clock for programming the

start up or stopping of the

genset

INDICATORS

Un groupe électrogène équipé

avec un coffret électrique ACP

0411 ATS peut être démarré

automatiquement dans quelques

seconds (15-20) à partir de

l’activation du signal d’àrrêt dans

la fourniture du secteur.

E

I

Un grupo electrógeno equipado

con un cuadro electric ACP 0411

ATS

puede

ser

arrancado

automaticamente

dentro

de

algunos segundos (15-20) de la

activación de la señal de falta de

la erogación de la red eléctrica.

Un gruppo elettrogeno collegato

con un quadro automatico ACP

0411 ATS può essere avviato

automaticamente entro pochi

secondi (15-20) dall’attivazione

del segnale che indica un arresto

nella

fornitura

della

linea

principale.

PERFORMANCES

PRESTACIONES

• Démarrage automatique à 4 • Arranque automático a 4

impujados

impulsions

inmediato

o

• Démarrage

immediate

ou • Arranque

retrasado después falta red

retardé après manqué tension

eléctrica

réseau

automática

• Surveillance automatique des • Monitorización

faltas grupo

anomalies

• Autotest semanal

• Autotest hebdomadaire

• Arrêt immediate ou retardé au • Parada inmediata o retrasada

depués de la vuelta del voltaje

retour de la tension réseau

red

• Protections moteur

• Recharge batterie contrôlée en • Protecciones motor

courant et en tension

• Cargamiento

batería

con

control de corriente y de

• Horloge

pour

la

voltaje

programmation

de

le

• Reloj para la programación del

démarrage et de l’arrêt

arranque o de la parada del

generador

INDICATEURS

INDICADORES

PRESTAZIONI

• Avviamento automatico con 4

impulsi

• Avviamento

immediate

o

ritardato dopo mancanza rete

• Sorveglianza

automatica

anomalie gruppo elettrogeno

• Autotest settimanale

• Arresto immediato o ritardato

al ritorno tensione rete

• Protezioni del motore

• Ricarica batteria controllata in

corrente e in voltaggio

• Orologio

per

la

programmazione

dell’avviamento

o

dello

spegnimento del generatore

INDICATORI

Mains voltmeter

Generator voltmeter (1 phase)

Generator ammeter (as option)

Generator frequency meter

Hour meter

Battery voltmeter

Fuel level indicator

Voltmètre secteur

Voltmètre génerateur (1 phase)

Ampèremètre génerateur (en

option)

Fréquencemètre génerateur

Compteur horaire

Voltmètre batterie

Niveau combustible

Voltimetro red

Voltimetro generador (1 fase)

Amperimetro generador (como

opción)

Frecuencimetro generador

Medidas horas de marcha

Voltimetro batería

Nivel carburante

PROTECTIONS

PROTECTIONS

PROTECCIONES

Indicatore tensione rete

Indicatore tensione generatore (1

fase)

Amperometro generatore (in

opzione)

Indicatore frequenza generatore

Contaore

Indicatore tensione batteria

Livello carburante

PROTEZIONI

Anomalía grupo

Elevada temperature motor

(como opción)

Sobrefrecuencia

Baja presión aceite

Sobrecarga

Batería sin carga

Bajo nivel combustible

Anomalie generatore

Alta temperatura motore (in

opzione)

Sovrafrequenza

Bassa pressione olio

Sovraccarico

Batteria non carica

Livello di carburante basso

Generator failure

High engine temperature

option)

Overfrequency

Low oil pressure

Overcrank

Battery not charged

Low fuel level

TECNOGEN SpA

Anomalie générateur

(as Haute temperature moteur (en

option)

Surfréquence

Basse pression huile moteur

Surcharge groupe

Batterie non chargée

Bas niveau carburant

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

6

AUTOMATIC CONTROL PANEL

COFFRET ELECTRIQUE AUTOMATIQUE

CUADRO ELECTRICO AUTOMATICO

QUADRO ELETTRICO AUTOMATICO

COMPLETE CONTROL PANEL FREE STANDING TYPE

1)

Equipment: control board, circuit breaker, battery charger, transfer switch, box key.

COFFRET ELECTRIQUE COMPLET TYPE ARMOIRE SEPARE DU GROUPE

Equipement : carte électronique de contrôle, disjoncteur de protection, chargeur de batterie, inverseur de source, clé coffret.

CUADRO ELECTRICO COMPLETO EN ARMARIO SEPARADO DEL GRUPO

Equipamiento: carta electronica de controllo, interruptor magnetotermico, cargador de bateria, transferencial, llave quadro.

QUADRO ELETTRICO COMPLETO SEPARATO DAL GRUPPO

Equipaggiamento: scheda elettronica di controllo, interruttore magnetotermico, carica batteria, telecommutazione e chiave quadro.

AMF CONTROL PANEL FITTED ON THE GEN-SET WITHOUT TRANSFER SWITCH

Equipment: control board, circuit breaker, battery charger, box key.

COFFRET ELECTRIQUE MONTE SUR LE GROUPE SANS INVERSEUR DE SOURCE

Equipement : carte électronique de contrôle, disjoncteur de protection, chargeur de batterie, clé coffret.

CUADRO ELECTRICO MONTADO SOBRE EL GRUPO SIN TRANSFERENCIAL

Equipamiento: carta electronica de controllo, interruptor magnetotermico, cargador de bateria, llave quadro.

QUADRO ELETTRICO MONTATO SUL GRUPPO ELETTROGENO SENZA TELECOMMUTAZIONE

Equipaggiamento: scheda elettronica di controllo, interruttore magnetotermico, carica batteria, chiave quadro.

CONTROL PANEL FITTED ON THE GEN-SET WITH TRANSFER SWITCH SUPPLIED IN A SEPARATED BOX

Equipment: control board, circuit breaker, battery charger, box key, separate transfer switch.

ACP

7320

ATS

2)

ACP

7320

AMF

3)

ACP

7320

COFFRET ELECTRIQUE MONTE SUR LE GROUPE + INVERSEUR DE SOURCE FOURNI DANS UN COFFRET SEPARE

Equipement : carte électronique de contrôle, disjoncteur de protection, chargeur de batterie, inverseur de source separé, clé coffret.

STS

CUADRO ELECTRICO MONTADO SOBRE EL GRUPO CON TRANSFERENCIAL SEPARADO

Equipamiento: carta electronica de controllo, interruptor magnetotermico, cargador de bateria, llave quadro, transferencial

separado.

QUADRO ELETTRICO MONTATO SUL GRUPPO ELETTROGENO CON TELECOMMUTAZIONE SEPARATA

Equipaggiamento: scheda elettronica di controllo, interruttore magnetotermico, carica batteria, chiave quadro, telecommutazione in

armadio separato.

DSE 7320

CONTROL BOARD

CARTE ELECTRONIQUE DE CONTROL

CARTA ELECTRONICA DE CONTROL

SCHEDA ELETTRONICA DI CONTROLLO

GB

F

E

I

The DSE7320 is an Automatic Mains

Failure Control Module designed to

automatically start and stop diesel

generating sets that include electronic

and non electronic engines. The module

also provides excellent genset monitoring

and protection features.

FEATURES

Stop/reste – Auto – Manual – Start

LCD display scroll

Event log view

Acustic alarm

DIGITAL MEASURING

Generator volts (3 phases)

Generator amperes (3 phases)

Generator frequency

KW-meter

kVA-meter

Cos ϕ- meter

Rpm meter

Water temperature (optional)

Oil pressure (optional)

Gen set hours counter

Mains volts

Battery volts

Mains frequency

Charging voltage

Start-counter

Fuel level %

INDICATORS

Mains live

Generator live

Mains contactor closed

Generator contactor closed

Engine running

PROTECTIONS

Low oil pressure

High engine temperature

Low fuel level

Fail to start

Fail to stop

Emergency stop

Over/under frequency

Over/under voltage

Over/under speed

Fuel level

Belt breakage

Over current

Over/under battery voltage

La DSE7320 est une carte de contrôle

projetée pour démarrer et arrêter

automatiquement groupes électrogènes

diesels avec moteurs électroniques et

non électroniques. La carte représente un

système excellent de contrôle et de

protection du groupe électrogène.

EQUIPEMENT

Fiche électronique de contrôle DSE7320

Disjoncteur de protection

Chargeur de batterie

Bouton poussoir arrête d’émergence

MESURES NUMERIQUES

Voltmètre générateur (3 phases)

Ampèremètre générateur (3 phases)

Fréquencemètre générateur

KW-mètre

kVA- mètre

Cos ϕ- mètre

Tm mètre

Température eau (facultatif)

Pression huile (facultatif)

Totalisateur d’heures de marche

Voltmètre secteur

Voltmètre batterie

Fréquence réseau

Tension de charge

Compteur démarrages

Niveau combustible %

INDICATEURS

Présence secteur

Présence tension générateur

Inverseur secteur fermé

Inverseur générateur fermé

Moteur en marche

PROTECTIONS

Bas pression huile moteur

Haute température moteur

Bas niveau combustible

Non démarrage

Non arrêt

Arrêt d’urgence

Sur/sous fréquence

Sur/sous voltage

Sur/sous vitesse

Niveau de combustible

Rupture courroie

Surcourant

Sur/sus la tension de batterie

La DSE7320 es una carta de control para

arranquar y parar automáticamente grupos

electrógenos diesel con motores electrónicos y

no electrónicos. La carta constituye un

excelente sistema de control y protección del

grupo electrógeno.

La DSE7320 è una scheda di controllo

progettata

per

avviare

e

arrestare

automaticamente gruppi elettrogeni diesel

con motori elettronici e non elettronici. La

scheda costituisce un eccellente sistema di

controllo e di protezione del gruppo

elettrogeno.

EQUIPAGGIAMENTO

Scheda elettronica di controllo DSE7320

Interruttore magnetotermico

Carica batteria

Pulsante stop emergenza

MISURAZIONI DIGITALI

Voltmetro tensione generatore (3 fasi)

Amperometro generatore (3 fasi )

Frequenzimetro generatore

KW- metro

kVA- metro

Cos ϕ-metro

Gm metro

Temperatura acqua (facoltativo)

Pressione olio (facoltativo)

Contaore di funzionamento gruppo

Voltmetro tensione rete

Voltmetro batteria

Frequenza rete

Tensione di carica

Contavviamenti

Livello carburante %

INDICATORI

Presenza tensione di rete

Presenza tensione generatore

Erogazione da rete

Erogazione da gruppo

Motore avviato

PROTEZIONI

Bassa pressione olio

Alta temperatura motore

Basso livello di carburante

Mancato avviamento

Mancato arresto

Stop d’emergenza

Sovra/sotto frequenza

Sovra/sotto voltaggio

Sovra/sotto velocità

Livello del carburante

Rottura cinghia

Sovracorrente

Sovra/sotto tensione della batteria

TECNOGEN SpA

EQUIPMENT

Ficha electrónica de control DSE7320

Interruptor magnetorermico

Cargador de batería

Boton de parada de emergencia

MEDIDAS DIGITALES

Voltimetro (3 fases)

Amperimetro (3 fases)

Frecuencimetro

KW- metro

kVA- metro

Cos ϕ-metro

Revolutiones por minuto metro

Termometro agua (opcional)

Presión aceite (opcional)

Medida horas de marcha

Voltimetro tensión de red

Voltimetro batería

Frequencia red

Tensión de carga

Numero de arranques

Nivel carburante %

INDICADORES

Presencia tensión de red

Presencia tensión grupo

Transferencial red cerrado

Transferencial grupo cerrado

Motor en marcha

PROTECCIONES

Baja presión aceite

Elevada temperatura motor

Baja nivel carburante

Falta de arranque

Falta de parada

Parada de emergencia

Sobre/bajo frecuencia

Sobre/bajo voltaje

Sobre/bajo velocitad

nivel de combustibile

Ruptura correa

Corriente maxima

Sobre/bajo voltaje de la batería

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

7

SOUNDPROOF CANOPY

CAPOTE D’INSONORISATION

CAPOTA DE INSONORIZACION

CABINA INSONORIZZATA

GB

The

TecnoGen

Super

Silent

soundproof canopy has been

designed with the aim of achieving

the maximum noise level reduction

and to provide a perfect cooling of

the engine. The cooling airflow is

forced through fixed circuits. The

canopy is suitable for tropical

ambient application. The exhaust

gas silencer is residential type

internally mounted. The canopy is

completely built of hot galvanized

carbon sheet steel. The sheets

have a thickness 20/10. The

structure is fully bolted, fixed by a

special

polyethylene

sealing,

completely free from electrical

installation. All the panels can be

easily removed. The cab is

provided with doors of wide

opening for easy access to

generating set for the maintenance

operations.

The

soundproofing

materials are highly fire resistant

and self-extinguishing.

F

E

I

La capote insonorisée TecnoGen

Super Silent à été conçue pour

atteindre le niveau de bruit le mineur

possible et un refroidissement du

moteur parfait. Le souffle d’air

refroidissant est canalisé en circuits

fixes. La capote est apte à être

utilisée dans les ambiances tropicales.

Le silencieux des gaz d’échappement,

de type résidentiel, est mis à

l’intérieur de la capote. La cabine est

construite en acier galvanisé à chaud.

Les tôles ont une épaisseur de 20/10.

La

structure

est

complètement

boulonnée et fixée à travers des

garnitures spéciales au polyéthylène.

Tous les panneaux sont facilement

amovibles. La cabine est dotée de

portes avec grandes ouvertures qui

permettent un accès facile au groupe

électrogène pour les opérations de

manutention.

Les

matériaux

d’insonorisation

sont

fortement

résistant au feu et auto-extinguibles.

La capota insonorizada TecnoGen

Super Silent tiene sido planeada

con el objetivo de alcanzar el

menor

nivel

de

rumorosidad

posible y un perfecto enfriamiento

del motor. El soplo de aire es

canalizado en circuitos fijos. La

cabina es apta a ser utilizada en

ambientes tropicales. El silenciador

de los gases de descargue, de tipo

residencial, es colocado dentro de

la cabina. La cabina es construida

en acero cincado. Las chapas

tienen un espesor de 20/10. La

estructura

es

completamente

bullonata y montada con sellos

especiales de polietilene. Todos los

paneles son fácilmente removibles.

La cabina es dotada con puertas

con

amplias

aberturas

que

permiten el fácil acceso al grupo

electrógeno por las operaciones de

manutención.

Los

materiales

insonorizantes son muy resistentes

al fuego y auto-exinguentes.

La cabina insonorizzata TecnoGen

Super Silent è stata progettata allo

scopo di raggiungere il minor livello

di rumorosità possibile e un perfetto

raffreddamento del motore. Il soffio

d’aria raffreddante è canalizzato in

circuiti fissi. La cabina è adatta ad

essere

utilizzata

in

ambienti

tropicali. Il silenziatore dei gas di

scarico, di tipo residenziale, è

collocato all’interno della cabina. La

cabina è costruita in acciaio zincato

a caldo. Le lamiere hanno uno

spessore di 20/10. La struttura è

completamente bullonata e fissata

tramite speciali sigilli al polietilene.

Tutti i pannelli sono facilmente

rimovibili. La cabina è dotata di

porte con ampie aperture che

consentono il facile accesso al

gruppo elettrogeno per le operazioni

di

manutenzione.

I

materiali

insonorizzanti

sono

altamente

resistenti al fuoco e autoestinguenti.

Our quality in 10 points

Notre qualité résumée en 10 points

Nuestra calidad en 10 puntos

La nostra qualità in 10 punti

1

Internal residential silencer for lower sound levels

Silencieux interne pour un niveau bas de bruit

Silenciador interno para un nivel de rumorosidad más bajo

Silenziatore interno per un livello di rumorosità piú basso

2

Integrated fuel tank of different sizes

Réservoirs de combustible disponibles, sur demande, de capacité supérieure

Tanques integrados disponibles, como opción, de capacidad superior

Serbatoi integrati disponibili, su richiesta, di capacità superiore

3

Control panel viewing window to easily check status of generating set

Fenêtre de visualisation du panneau de contrôle pour un contrôle plus facile du status opérationnel du groupe

Ventana de visualización del panel de control por un más fácil control del estatus operativo del grupo

Finestra di visualizzazione del pannello di controllo per un piú facile controllo dello status operativo del gruppo

4

Lockable access doors for extra safety and security

Porte d’accès avec serrure pour une sûreté majeure

Puertas de acceso con cerradura para una mayor seguridad

Porte di accesso con serratura per una maggiore sicurezza

5

Galvanized bolts

Boulons galvanisés

Pernos cincados

Bulloni zincati

6

Emergency stop button

Interrupteur d’arrêt d’urgence

Botón parada de emergencia

Pulsante arresto di emergenza

7

Doors location convenient to controls and service area

Placement des portes pour rendre les contrôles plus faciles

Colocación de las puertas para facilitar los controles

Collocazione delle porte per facilitare i controlli

8

High serviceability level

Haut niveau d’accessibilité pour la manutention

Alto nivel de accesibilidad para la manutención

Alto livello di accessibilità per la manutenzione

9

Central lifting hook

Crochet central d’enlèvement

Gancho de elevación

Gancio di sollevamento centrale

10

TECNOGEN SpA

Galvanized metal steel sheet pre-treated prior to powder coating

Tôles en acier galvanisé pré-traitées avant le vernissage à poudre

Chapas de acero cincado pre-tratadas antes de la pintura a polvo

Lamiere di acciaio zincato pre-trattate prima della verniciatura a polvere

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

8

OPEN SKID VERSION DRAWING

DESSIN VERSION SUR SKID

DIBUJO VERSION ABIERTA

DISEGNO VERSIONE APERTA

TECNOGEN SpA

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

9

SOUND PROOF VERSION DRAWING

DESSIN VERSION INSONORIZEE

DIBUJO VERSION INSONORISADA

DISEGNO VERSIONE INSONORIZZATA

TECNOGEN SpA

- postal address:

strada Ponteriglio, 25 – 29010 Pontenure (PC)- ITALY

Tel +39 0523 512440 - Fax +39 0523 504453 – E-mail: [email protected] - Web site: www.tecnogen.com

400 Series

403D-11G

Diesel Engine - ElectropaK

9.3 kWm @ 1500 rev/min

11.4 kWm @ 1800 rev/min

17.9 kWm @ 3000 rev/min

Powered by your needs

The 403D-11G ElectropaK is a powerful but quiet 1.1 litre naturally aspirated 3cylinder compact package

Compact, Clean, Efficient Power

Design features on the 400D range of ElectropaKs ensures clean rapid starting in all

conditions whilst delivering impressive performance with low operating costs in a

small, efficient package size

Lower Operating Costs

The 400 Series engine family

continues to set new standards in the

compact engine market. Developed

alongside customers to fulfill their

needs in the Genset, Compressor,

Agricultural and general Industrial

markets.

These new ElectropaKs provide

compact power, from a robust family

of 3 and 4 cylinder diesel engines

designed to provide economic and

durable operation at Prime and

Standby duties, hitting the key power

nodes required by the power

generation industry.

Long-term Power Solution

1500

1800

3000

The 400D range of ElectropaKs has been designed to fully comply with stringent EU

and EPA emissions regulations, providing an emissions compliant power solution for

the future

World-class Product Support

At Perkins we are constantly researching, developing and investing in our products

and services. Total worldwide support is provided through a network of distributors

and service outlets, providing access to over 50,000 parts and exchange units 24

hours a day, 365 days a year. This support is enhanced by TIPSS (The Integrated

Parts and Service System). TIPSS enables customers to electronically specify and

order parts as well as service 400 Series engines with online guides and service tools

Emissions statement

Engine Speed

The compact package size makes installation and transportation easier and more cost

effective

Operating and maintenance costs are reduced through excellent fuel and oil economy

Service intervals are set at 500 hours as standard and Perkins provides

comprehensive warranty cover for two years, with three years on major engine

components. A low usage warranty package is also available

Certified against the requirements of EU2007 (EU 97/68/EC Stage II) and EPA Tier 4

Final (EPA 40 CFR Part 1039 Tier 4) legislation for non-road mobile machinery,

powered by constant speed engines

Type of Operation

Prime Power

Standby Power

Prime Power

Standby Power

Prime Power

Standby Power

Typical Generator

Output (Net)

kVA

kWe

9.0

7.2

10.0

8.0

11.2

9.0

12.4

9.9

17.5

14.0

19.5

15.6

Engine Power

Gross

kWm

8.6

9.5

10.7

11.8

17.9

19.7

Net

bhp

11.5

12.7

14.3

15.8

24.0

26.4

kWm

8.4

9.3

10.3

11.4

16.1

17.9

bhp

11.4

12.6

13.8

15.3

22.8

25.2

The above ratings represent the engine performance capabilities to conditions specified in ISO 8528/1, ISO 3046/1:1986, BS 5514/1.

Derating may be required for conditions outside these; consult Perkins Engines Company Limited.

Generator powers are typical and are based on typical alternator efficiencies and a power factor (cos θ) of 0.8.

Fuel specification: BS 2869: Part 2 1998 Class A2 or ASTM D975 D2.

Rating Definitions

Prime Power: Power available at variable load in lieu of a main power network. Overload of 10% is permitted for 1 hour in every 12 hours operation.

Standby (maximum): Power available at variable load in the event of a main power network failure. No overload is permitted.

Photographs are for illustrative purposes only and may not reflect final specification.

All information in this document is substantially correct at time of printing and may be altered subsequently

Publication No. 1910/05/08 Produced in England ©2008 Perkins Engines Company Limited

400 Series

403D-11G

Standard ElectropaK Specification

Air Inlet

449 mm

776 mm

Mounted air filter

700 mm

Fuel System

Mechanically governed cassette type fuel injection pump

Split element fuel filter

Lubrication System

Wet steel sump with filler and dipstick

Spin-on full-flow lub oil filter

Cooling System

Thermostatically-controlled system with belt driven coolant pump and

pusher fan

Mounted radiator, piping and guards

Electrical Equipment

12 volt starter motor and 12 volt 15 amp alternator with DC output

Oil pressure and coolant temperature switches

12 volt shut-off solenoid energised to run

Glow plug cold start aid and heater/starter switch

Flywheel and Housing

1500/1800 rev/min

High inertia flywheel to SAE J620 Size 6½ Heavy

Flywheel housing SAE 5 Long

3000 rev/min

High inertia flywheel to SAE J620 Size 6½ Light

Flywheel housing SAE 5 Short

Mountings

Front and rear engine mounting brackets

Optional Equipment

Workshop manual

Parts book

Fuel Consumption

Engine Speed

g/kwh

l/hr

Standby

268

3.6

Prime power

248

3.0

75% of prime power

257

2.3

50% of prime power

280

1.7

General Data

Number of cylinders

Cylinder arrangement

Cycle

Aspiration

Combustion system

Compression ratio

Bore and Stroke

Displacement

Direction of rotation

Cooling system

Total coolant capacity

Total lubrication

system capacity

Length

Width

Height

Total weight (dry)

3

Vertical in-line

4 stroke

Naturally aspirated

Indirect injection

23:01

77 x 81 mm

1.131 litres

Anti-clockwise

viewed on flywheel

Water cooled

5.2 litres

4.9 litres

776 mm

449 mm

700 mm

129.2 kg

Final weight and dimensions will depend on completed specification.

Perkins Engines Company Limited

Peterborough PE1 5NA

United Kingdom

Telephone +44 (0)1733 583000

Fax +44 (0)1733 582240

www.perkins.com

All information in this document is substantially correct at time of printing and may be altered subsequently

Publication No. 1910/05/08 Produced in England ©2008 Perkins Engines Company Limited

Distributed by

Réf. 2063 en - 10.2007/e

35

30

25

20

15

10

ALTERNATORS

LSA 37 - 4 Pole - Three phase

Electrical and mechanical data

ALTERNATORS

LSA 37 - 4P

50 Hz - 1500 r.p.m.

TYPICAL DATA

Insulation class

Winding pitch - Code

Wires

Drip proof

Altitude

Overspeed

Air flow

H

1 - (N° 1)

12

IP 23

≤ 1000 m

2250 min -1

0,04 m3/s

Excitation system

A.V.R. model

Voltage regulation (steady state)

Sustained short-circuit current

Total harmonic (*) TGH / THC

Wave form : NEMA = TIF - (*)

Wave form : I.E.C. = THF - (*)

Shunt

R 250

± 0,5 %

<3%

< 50

<2%

(*) Total harmonic content line to line, at no load or full rated linear and balanced load

RATINGS : kVA / kW - Power factor = 0,8

Duty/Ambiant T°

Class/T° rise

Phase

Y

∆

37 M5

37 M6

37 M7

37 VL8

Continuous / 40°C

H / 125° K

3 ph.

380V

220V

400V

230V

F / 105° K

3 ph.

1 ph.

∆∆

415V

240V

230V

380V

220V

400V

230V

Stand-by / 40°C

H / 150° K

3 ph.

1 ph.

415V

240V

∆∆

380V

220V

230V

400V

230V

415V

240V

Stand-by / 27°C

H / 163° K

3 ph.

1 ph.

∆∆

230V

380V

220V

400V

230V

1 ph.

415V

240V

∆∆

230V

kVA

7,5

4,5

7

4

8

5

8,5

5,5

kW

6

3,6

5,6

3,2

6,4

4

6,8

4,4

kVA

9

5,5

8

5

9,5

6

10

6

kW

7,2

4,4

6,4

4

7,6

4,8

8

4,8

kVA

13

8

12

7,5

14

8,5

14,5

9

kW

10,4

6,4

9,6

6

11,2

6,8

11,6

7,2

kVA

17

10

15,5

9,5

18

11

19

11,5

kW

13,6

8

12,4

7,6

14,4

8,8

15,2

9,2

EFFICIENCIES (%) : Class H . 40° C

Three phase : 400 V

P.F. = 0,8

Single phase : 230 V

P.F. = 0,8

P.F. = 1

P.F. = 1

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

37 M5

75,5

82

83,3

83,2

82,8

78,1

85,9

88,2

89

88,9

65,1

74,6

77,1

77,7

77,2

67,2

78,3

82

83,7

83,7

37 M6

77,2

82,7

83,3

82,7

82

80

86,8

88,6

89

88,8

68,8

76,3

77,5

76,9

76,1

75

82,3

83,7

83,6

83,1

37 M7

81,8

86

86,3

85,5

85

84,2

89,5

90,6

90,7

90,5

74,7

80,7

81,3

80,5

79,9

80

85,6

86,4

85,8

85,3

37 VL8

85,1

88,6

88,7

87,9

87,5

87

91,3

92,1

92

91,8

78,7

84

84,4

83,6

83,1

83,2

87,9

88,4

87,8

87,3

REACTANCES (%) - TIME CONSTANTS (ms) : CLASS : H / 400 V

Kcc

Short-circuit ratio

Direct axis synchronous reactance unsaturated

Xd

Xq

Quadrature axis synchronous reactance unsaturated

Open circuit time constant

T'do

X'd

Direct axis transient reactance saturated

Short circuit transient time constant

T'd

X"d

Direct axis subtransient reactance saturated

Subtransient time constant

T"d

X"q

Quadrature axis subtransient reactance saturated

Zero sequence reactance unsaturated

Xo

X2

Negative sequence reactance saturated

Armature time constant

Ta

OTHER DATA - CLASS : H / 400 V io

ic

uc

ms

kVA

%

W

W

No load excitation current (A)

Full load excitation current (A)

Full load excitation voltage (V)

Recovery time(∆U =20 % trans.)

Motor start. (∆U = 20% sust.) or (∆U = 50% Transient)

Transient dip (rated step load) - PF : 0,8 LAG

No load losses

Heat rejection

37 M5

1

140

70

522

9,9

40

4,9

3,7

8,5

9,9

6,7

6

37 M6

0,87

160

80

522

11,3

40

5,7

3,7

9,8

11,3

7,7

6

37 M7

0,71

183

90

565

12

40

6

3,7

10,6

12

8,3

6

37 VL8

0,58

198

100

602

12,2

40

6,1

3,7

10,9

12,2

8,5

6

0,87

2,03

40

< 300

20

15,5

380

1128

0,88

2,3

45

< 300

22

16,7

384

1336

0,79

2,3

45

< 300

30

16,8

426

1624

0,64

2,05

40

< 300

38

15,8

438

1704

According to : I.E.C. 34.1/34.2 - U.T.E. : NF C 51.111 - V.D.E. 0530 - B.S. 4999 & 5000 - NEMA : MG 1.22 - ISO 8528 . 3 - CSA (C22.2+UL 2200)

.Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

ALTERNATORS

LSA 37 - 4P

50 Hz - 1500 r.p.m.

TRANSIENT VOLTAGE VARIATION - 400V

Load application

30

Load rejection

40

M5 M6

M5 M6

M7

M7

35

25

20

% Voltage rise

% Voltage dip

30

VL8

15

10

VL8

25

20

15

10

5

5

0

0

0

5

10

15

20

25

0

kVA at 0,8 power factor

5

10

15

20

25

30

kVA at 0,8 power factor

Motor starting

M5 M6

40

M7

VL8

% Voltage dip

30

20

10

0

0

5

10

15

20

25

30

35

Locked rotor

1) For a starting P.F. differing from 0,6 the starting kVA have to be multiplied by (Sine Ø /0,8)

2) If voltage is not 400V(Y) , 230V(∆) at 50 Hz then kVA must be multiplied by (400/U)2 or (230/U)2.

Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

ALTERNATORS

LSA 37 - 4P

60 Hz - 1800 r.p.m.

TYPICAL DATA

Insulation class

Winding pitch - Code

Wires

Drip proof

Altitude

Overspeed

Air flow

H

1 - (N° 1)

12

IP 23

≤ 1000 m

2250 min -1

0,06 m3/s

Excitation system

A.V.R. model

Voltage regulation (steady state)

Sustained short-circuit current

Total harmonic (*) TGH / THC

Wave form : NEMA = TIF - (*)

Wave form : I.E.C. = THF - (*)

Shunt

R 250

± 0,5 %

<3%

< 50

<2%

(*) Total harmonic content line to line, at no load or full rated linear and balanced load

RATINGS : kVA / kW - Power factor = 0,8

Duty/Ambiant T°

Class/T° rise

Phase

Y

∆

YY

37 M5

37 M6

37 M7

37 VL8

Continuous / 40°C

H / 125° K

3 ph.

1 ph.

380V 416V 440V 480V

240V

208V 220V 240V

F / 105° K

3 ph.

∆∆

Stand-by / 40°C

H / 150° K

3 ph.

1 ph.

1 ph.

∆∆

380V 416V 440V 480V

240V

240V

208V 220V 240V

240V

380V 416V 440V 480V

240V

208V 220V 240V

∆∆

240V

Stand-by / 27°C

H / 163° K

3 ph.

1 ph.

380V 416V 440V 480V

240V

208V 220V 240V

∆∆

240V

kVA

8

9

9,5

10

5

7

8

8,5

9

4,5

9

9,5

10

11

5,5

9,5

10

11

12

6

kW

6,5

7,2

7,6

8

4

5,5

6,4

6,8

7,2

3,6

7

7,6

8

8,8

4,4

7,5

8

8,8

9,6

4,8

kVA

10

11

11,5 12,5

12,5 13,5

kW

8

8,8

9,2

10

kVA

14

15

16

kW

11

12

12,8

kVA

16

18

19

kW

13

6

9

10

10,5

11

5,5

10,5 11,5

12

13

6,5

11

12

4,8

7

8

8,4

8,8

4,4

8,5

9,2

9,6

10,4

5,2

9

9,6

17,5

9

12,5

14

14,5 15,5

8

15

16

17

18,5

9

15

16,5 17,5

14

7,2

10

11,2 11,6 12,4

6,4

12

7,2

12

13,2

14

21

11

15

16,5 17,5

19

10

18

20

21

23

12

8,8

12

13,2

15,2

8

14,4 15,2 16,8

14

12,8 13,6 14,8

19

20,5 22,5 11,5 18,5

14,5 15,2 16,4

18

9,2

15

16

10

7

10,8

5,6

19

9,5

15,2

7,6

16,8 18,4

9,6

EFFICIENCIES (%) : Class H . 40° C

Three phase : 480 V

P.F. = 0,8

Single phase : 240 V

P.F. = 0,8

P.F. = 1

P.F. = 1

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

1/4

2/4

3/4

4/4

St.by

37 M5

75,7

82,8

84,3

84,5

84,1

77,9

86,1

88,6

89,5

89,5

70,3

79

81,1

81,3

81,1

71,9

81,8

84,9

85,9

86

37 M6

78,3

83,8

84,5

83,9

83,3

80,8

87,5

89,2

89,6

89,5

73,4

80,3

81,3

80,7

80,2

78,6

85

86

85,6

85,2

37 M7

82

86,6

87,2

86,6

86,2

84

89,6

91

91,1

91

77

82,8

83,4

82,6

82,1

81,7

86,9

87,5

86,8

86,4

37 VL8

84,5

88,8

89,3

88,9

88,6

86,1

91,1

92,2

92,4

92,3

78,7

84,4

85

84,3

83,8

83

88

88,6

88

81,6

REACTANCES (%) - TIME CONSTANTS (ms) : CLASS : H / 480 V

Kcc

Short-circuit ratio

Direct axis synchronous reactance unsaturated

Xd

Xq

Quadrature axis synchronous reactance unsaturated

Open circuit time constant

T'do

X'd

Direct axis transient reactance saturated

Short circuit transient time constant

T'd

X"d

Direct axis subtransient reactance saturated

Subtransient time constant

T"d

X"q

Quadrature axis subtransient reactance saturated

Zero sequence reactance unsaturated

Xo

X2

Negative sequence reactance saturated

Armature time constant

Ta

OTHER DATA - CLASS : H / 480 V io

ic

uc

ms

kVA

%

W

W

No load excitation current (A)

Full load excitation current (A)

Full load excitation voltage (V)

Recovery time(∆U =20 % trans.)

Motor start. (∆U = 20% sust.) or (∆U = 50% Transient)

Transient dip (rated step load) - PF : 0,8 LAG

No load losses

Heat rejection

37 M5

0,93

150

75

522

10,6

40

5,3

3,7

9,1

10,6

7,2

6

37 M6

0,76

183

90

522

13

40

6,5

3,7

11,2

13

8,8

6

37 M7

0,66

197

100

565

12,9

40

6,5

3,7

11,4

12,9

8,9

6

37 VL8

0,57

202

100

602

12,4

40

6,2

3,7

11,2

12,4

8,7

6

0,86

2,05

40

< 300

25

16,1

505

1321

0,86

2,42

47

< 300

30

18

505

1693

0,78

2,28

45

< 300

40

17,6

569

1912

0,63

1,95

38

< 300

50

16

597

1897

According to : I.E.C. 34.1/34.2 - U.T.E. : NF C 51.111 - V.D.E. 0530 - B.S. 4999 & 5000 - NEMA : MG 1.22 - ISO 8528 . 3 - CSA (C22.2+UL 2200) .

Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

ALTERNATORS

LSA 37 - 4P

60 Hz - 1800 r.p.m.

TRANSIENT VOLTAGE VARIATION - 480 V

Load application

30

Load rejection

40

M5 M6

M7

35

VL8

30

20

% Voltage rise

% Voltage dip

25

15

10

M5 M6

M7

VL8

25

20

15

10

5

5

0

0

0

5

10

15

20

25

30

0

5

kVA at 0,8 power factor

10

15

20

25

30

35

kVA at 0,8 power factor

Motor starting

40

M5 M6

M7

VL8

% Voltage dip

30

20

10

0

0

5

10

15

20

25

30

35

40

Locked rotor

1) For a starting P.F. differing from 0,6 the starting kVA have to be multiplied by (Sine Ø /0,8)

If voltage is not 480V(Y), 277V(∆), 240V(YY ) at 60 Hz then kVA must be multiplied by (480/U)2 or (277/U)2 or (240/U)2.

Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

ALTERNATORS

LSA 37 - 4P

Single bearing

DIMENSIONS

L

LB

AH

Xg

ß°

358

- 0,050

- 0,080

Ø BX

G

4

+1

160 -2

0

- 0,127

ØP

ØN

Y DIA, X eq. sp. holes on U P.C.D.

Access to A.V.R.

and terminals

3

AIR INLET

AIR OUTLET

CC

5

C

230

286

14

110

11 DIA, XBG eq. sp. holes on M P.C.D.

18

4 POLE

FRAME DIMENSIONS : S.A.E. 5 (without hand space)

L

LB

C

CC

Xg

Weight

J (kg.m2)

LSA 37 M5

492

430

216

80

220

90

0,0873

LSA 37 M6

492

430

216

80

220

90

0,0873

LSA 37 M7

532

470

216

80

240

105

0,1075

216

80

275

125

TYPE

LSA 37 VL8

592

530

S.A.E. 3 - 4 - 5 (with hand space)

0,1478

4 POLE

L

LB

C

CC

Xg

Weight

J (kg.m2)

LSA 37 M5

517

455

241

116

255

95

0,0933

LSA 37 M6

517

455

241

116

255

95

0,0933

LSA 37 M7

557

495

241

116

275

110

0,1149

LSA 37 VL8

617

555

241

116

310

130

0,1582

TYPE

With no specific mention the LSA 37 single bearing SAE 5 is supplied with flange without hand space.

FLANGE DIMENSIONS (without hand space)

S.A.E.

P

N

M

XBG

ß°

5

364

314,325

333,375

8

22° 30'

S.A.E. 3 - 4 - 5 (with hand space)

3

465

409,575

428,625

12

15°

4

406

361,95

381

12

15°

5

406

314,325

333,375

8

22° 30'

FLEX PLATE DIMENSIONS

Coupling

S.A.E.

BX

U

X

Y

AH

S.A.E.

3

11 1/2

352,42

333,38

8

11

39,6

11 1/2

10

314,32

295,28

8

11

53,8

10

•

•

8

263,52

244,48

6

11

62

8

7 1/2

241,3

222,25

8

9

30,2

7 1/2

6 1/2

215,9

200,02

6

9

30,2

6 1/2

4

5

•

•

•

•

•

•

Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

ALTERNATORS

LSA 37 - 4P

Two bearing

DIMENSIONS

L

58

5

LB

Xg

1 hole M12x28

Ø 364

-0

Ø 266,7 - 0,127

k6

Ø 38

M10 DIA, 8 eq. sp. holes

on 285,75 P.C.D.

22°30'

Access to A.V.R.

and terminals

10

G

41

4

+1

160 -2

358

8

AIR INLET

185

230

286

AIR OUTLET

18

14

67

C

18

4 POLE

FRAME DIMENSIONS (mm)

L

LB

C

Xg

Weight

J (kg.m2)

LSA 37 M5

513

455

171

240

95

0,0933

LSA 37 M6

513

455

171

240

95

0,0933

LSA 37 M7

553

495

171

260

110

0,1149

LSA37 VL8

613

555

171

305

130

0,1582

TYPE

Products and materials shown in this catalogue may, at any time, be modified in order to follow the latest technological developments, improve the design or change conditions of utilization.

Their description cannot, in any case, engage Leroy-Somer liability. The values indicated are typical values .

®

DSECONTROL

MONITORING

WITH

INTELLIGENCE.

®

DSE7310

& DSE7320

AUTO START & AUTO MAINS FAILURE CONTROL MODULES (COMMUNICATIONS & EXPANSION)

SPECIFICATION

DC SUPPLY

CONTINUOUS VOLTAGE RATING

8V to 35V Continuous

CRANKING DIP PROTECTION

Able to survive 0V for 50mS, providing supply

was at least 10V before dropout and supply

recovers to 5V. This is achieved without the need

for internal batteries

CHARGE FAIL/ EXCITATION

0V to 35V fixed power source 2.5W

MAXIMUM STANDBY CURRENT

160mA at 12V 80mA at 24V

MAXIMUM OPERATING CURRENT

340mA at 12V 160mA at 24V

ALTERNATOR INPUT

The DSE7310 and DSE7320 are

new control modules for single

gen-set applications. The modules

have been developed from the

successful DSE5310 and DSE5320

Series and incorporate a number

of advanced features to meet the

most demanding on-site

applications.

The DSE7310 is an Automatic Start

Control Module and the DSE7320

is an Auto Mains (Utility) Failure

Control Module. Both modules

have been designed to start and

stop diesel and gas generating

sets that include electronic and

non-electronic engines. The

DSE7320 includes the additional

capability of being able to monitor

a mains (utility) supply.

Both modules include USB, RS232

and RS485 ports as well as

dedicated DSENet® terminals for

expansion device connectivity.

The modules are simple to operate

and feature a newly designed

menu layout for improved clarity.

Enhanced features include a real

time clock for enhanced event and

performance monitoring, ethernet

communications for low cost

monitoring, mutual standby to

reduce engine wear and tear, trend

analysis to assist in the detection

of patterns in engine status and

preventative maintenance

designed to detect if engine parts

have developed fault conditions so

they can be replaced before a

major problem occurs.

FEATURES

• Backed up real time clock

• 132 x 64 pixel LCD display

• Configurable display languages

• USB connectivity

• Robust module enclosure

• Five-key menu navigation

• Durable soft touch membrane

buttons

• Fully configurable via PC software

• LED and LCD alarm indication

• Engine exercise mode

• Configurable start & fuel outputs

• kWh monitoring

• Automatic load transfer

• Eight configurable digital inputs

• Six configurable outputs

• Configurable timers and alarms

• Modbus RTU

• Magnetic pick-up

• Front panel programming

• Multiple date and time exercise

scheduler

• SMS messaging

• Power save mode

• PIN protected programming

• User selectable RS232 & RS485

communications

• DSENet® compatible

• Ethernet communications via

DSE860/865

• Customer logo display capability

• Multiple date and time

maintenance scheduler

• Configurable display pages

• Programmable load

shedding/acceptance

• Trend analysis

• Preventative maintenance

• kW overload protection

• Unbalanced load protection

• PDA compatible PC software

• Flexible sender input

• Configurable SCADA output page

NEW FEATURES

• True dual mutual standby with

load balancing timer

• Fan control for additional cooling

• ‘Protections Disabled’ facility

• Fuel usage monitoring and low

fuel alarm

• Support for up to three remote

display units

• Automatic sleep mode

• Easy access, configurable

diagnostics page shows summary

of output states

• Improved programmable event log

(250) showing date and time

• Manual fuel pump control

• Alternative configuration

• Multiple date and time scheduler

• 3 Programmable Maintenance

alarms with comms alert

• Customisable status screens

• Low fuel level alarm delay

• Charge alternator fail warning and

shutdown alarms with user

programmable delay

• Independent Earth fault trip

• Sleep mode

• Load switching (Load shedding

and dummy load outputs)

• Manual speed trim (on CAN

engines that support this feature)

• Additional display screens to help

with modem diagnostics

• Security levels – PC software has

password system to control

access to PC software features

• Operator configurable virtual LEDs

visible in SCADA

RANGE

15V - 333V (L-N) 50Hz - 60Hz

(Minimum 15V AC Ph-N)

ACCURACY

1% of full scale true RMS sensing

SUPPORTED TOPOLOGIES

3 phase 4 wire

3 phase 3 wire

Single phase 2 wire

2 phase 3 wire L1 & L2

2 phase 3 wire L1 & L3

MAINS/UTILITY INPUT (DSE7320 ONLY)

RANGE

15V - 333V (L-N) 50Hz - 60Hz

(Minimum 15V AC Ph-N)

ACCURACY

1% of full scale true RMS sensing

SUPPORTED TOPOLOGIES

3 phase 4 wire

3 phase 3 wire

Single phase 2 wire

2 phase 3 wire L1 & L2

2 phase 3 wire L1 & L3

CT’S

BURDEN

0.5VA

PRIMARY RATING

1A - 8000A (user selectable)

SECONDARY RATING

1A or 5A secondary (user selectable)

ACCURACY OF MEASUREMENT

1% of full load rating

RECOMMENDATIONS

Class 1 required for instrumentation

Protection class required if using for protection

Continued on page 2

SPECIFICATION

MAGNETIC PICKUP

VOLTAGE RANGE

+/- 0.5V minimum (during cranking) to 70V peak

FREQUENCY RANGE

10,000 Hz (max)

RELAY OUTPUTS

OUTPUT A (FUEL)

15 Amp DC at supply voltage

OUTPUT B (START)

15 Amp DC at supply voltage

OUTPUTS C & D

8 Amp 250V (Volt free)

AUXILIARY OUTPUTS E,F,G,H

2 Amp DC at supply voltage

DIMENSIONS

OVERALL

240mm x 181.1mm x 41.7mm

9.4” x 7.1” x 1.6”

PANEL CUT-OUT

220mm x 160mm

8.7” x 6.3”

Max panel thickness 8mm ( 0.3”)

TESTING

STANDARDS

ELECTRICAL SAFETY/

ELECTROMAGNETIC COMPATIBILITY

BS EN 60950

Safety of Information Technology Equipment,

including Electrical Business Equipment

BS EN 61000-6-2

EMC Generic Immunity Standard (Industrial)

BS EN 61000-6-4

EMC Generic Emission Standard (Industrial)

ENVIRONMENTAL

BS EN 60068-2-1

Cold Temperature -30oC

BS EN 60068-2-2

o

Hot Temperature +70 C

BS EN60068-2-30 HUMIDITY

Test Db cyclic

93% RH @ 40oC for 48 hours

BS EN 60068-2-6 VIBRATION

10 sweeps at 1 octave/minute in each of 3

major axes

5Hz to 8Hz @ +/-7.5mm constant displacement

8Hz to 500Hz @ 2gn constant acceleration

BS EN 60068-2-27 SHOCK

3 half sine shocks in each of 3 major axes

15gn amplitude, 11mS duration

BS EN 60529 DEGREES OF PROTECTION

PROVIDED BY ENCLOSURES

• IP65 (Front of module when installed into the

control panel with the supplied sealing

gasket)

NEMA RATING (APPROXIMATE)

• 12 (Front of module when installed into the

control panel with the supplied sealing

gasket)

BENEFITS

• 132 x 64 pixel ratio makes information easy to read

• Real time clock provides accurate event logging

• PC software is license free

• Set maintenance periods can be configured to maintain optimum engine

performance

• Ethernet communications provides advanced remote monitoring at low cost

• Modules can be integrated into building management systems

• Preventative maintenance avoids expensive engine down time

• Advanced PCB layout ensures high reliability

• Robust design

• Extensive performance monitoring

OPERATION

The modules are operated via the START, STOP, AUTO and MANUAL soft

touch membrane buttons on the front panel. The DSE7320 also has a TEST

button. Both modules include load switch buttons. The main menu system is

accessed using the five navigation buttons to the left of the LCD display.

CONFIGURATION

The modules can be configured using the front panel buttons or by using the

PC software and a USB lead.

COMMUNICATIONS

The DSE7310 & DSE7320 have a number of different communication

capabilities.

SMS Messaging

When the module detects an alarm condition, it has the ability to send an

SMS message to a dedicated mobile number (s), notifying an engineer of the

exact time, date and reason why the engine failed (GSM Modem and SIM

Card required).

Remote Communications

When the module detects an alarm state, it dials out to a PC notifying the

user of the condition (Modem required).

Remote Control

The module can be controlled remotely using either a GSM Modem, Ethernet via

DSE860/865 or via RS485. Using a modem allows the module to be controlled

from any distance. Using RS485 limits the distance to 1km (0.6 miles).

Building Management

The module has been designed to be integrated into new and existing

building management systems, using RS485.

PC Software

The module has the ability to be configured and monitored from a remote

PC, using the PC software and a USB lead.

INPUTS & OUTPUTS

Analogue inputs are provided for oil pressure, coolant temperature and fuel

level. These connect to conventional engine mounted resistive sender units

to provide accurate monitoring and protection facilities. They can also be

configured to interface with digital switch type inputs for low oil pressure and

high coolant temperature shutdowns. Eight user configurable digital inputs

are also included, plus one flexible sender.

Relays are provided for fuel solenoid output, start output and six additional

configurable outputs. On these configurable outputs a range of different

functions, conditions or alarms can be selected.

INSTRUMENTATION

The modules provide advanced metering facilities, displaying the information on

the LCD display. The information can be accessed using the five-key menu

navigation to the left of the display.

7310

7320

Generator Instruments

Volts, Hz, Amps, kW, kVA, Pf, kWh, kVAr,

kVArh, KVAh

Generator Instruments

Volts, Hz, Amps, kW, kVA, Pf, kWh, kVAr,

kVArh, KVAh

Engine Instruments

RPM, Oil Pressure, Coolant Temperature,

Hours Run, Charging Voltage, Battery Volts.

Engine Instruments

RPM, Oil Pressure, Coolant Temperature,

Hours Run, Charging Voltage, Battery Volts.

Electronic Engines

Enhanced Instrumentation and Engine ECU

diagnostics via electronic engine interface.

Electronic Engines

Enhanced instrumentation and Engine ECU

diagnostics via electronic engine interface.

Mains/Utility Instruments

Volts, Frequency, Amps (optional when

CT’s are fitted load side of the line)

ELECTRONIC ENGINE CAPABILITY

RELATED MATERIALS

TITLE

DSE7xxx Manual

DSE72xx/73xx PC

Software Manual

DSE2130 Data Sheet

DSE2157 Data Sheet

DSE2548 Data Sheet

DSE860/865 Data

Sheet

PART NO’S

057-074

057-077

053-060

053-061

053-062

055-071

DSENET®

DSENet® is a collection of expansion

modules that have been created to

work with DSENet® compatible

control modules. DSENet® allows up

to 20 different expansion devices to

be used at a time. 10 of these

devices can be of the same type

(excluding DSE2130). The expansion

modules available are:

Available Now

DSE2157 Relay Output Expansion

Module

DSE2130 Input Expansion Module

DSE2548 Annunciator Module

Remote Display Module

Coming Soon

FET Output Expansion Module

NFPA 110 Interface Module

Identification Dongle

EVENT LOG

The module includes a

comprehensive event log that shows

the most recent 250 alarm

conditions and the date and time

that they occurred. This function

assists the user when fault finding

and maintaining a generating set.

ELECTRONIC ENGINE

COMPATABILITY

• CAT

• Cummins

• Deutz

• John Deere

• MTU

• Perkins

• Scania

• Volvo

• IVECO

• Generic

• Plus additional manufacturers

®

DSE7310 & DSE7320

MECHANICAL INTERLOCK

LOAD

DSE7320 ONLY

CT’s 1 AMP OR 5 AMP

SECONDARY

PROTECTION CLASS

P1

P2

L1

L1

S1

L2

L2

L3

L3

N

N

2 AMP

FUSES

FROM

MAINS

(UTILITY)

2 AMP

FUSES

ELECTRICAL INTERLOCK

G

M

MPU

28

19

15

WL

CHARGE

ALT

CRANK

BATTERY NEGATIVE MUST BE GROUNDED

TERMINALS SUITABLE FOR 22-16 AWG (0.6mm - 1.3mm )

FIELD WIRING

TIGHTENING TORQUE = 0.8Nm (7lb-in)

47

48

49

50

R

L1

S

L2

T

L3

N

7

24

USB

PROGRAMMING PORT

ENGINE ECU

PLANT +VE

8 INPUTS

61

62

63

64

23

MPU

MAINS VOLTS

4 FET OUTPUTS

60

22

SCR

65

66

67

8

9

10

11

27

25

L

SENDER COMMON

18

30

SCR

SCR

FLEXIBLE

17

NOTE 1

FUEL

29

MODULE 7310/7320

SENDER

WATER

16

FUEL LEVEL SENDER

6

UPTO 32 AMPS

FUSE

MIN 2 AMP MAX 20 AMP

ANIT-SURGE FUSE

OIL

5

HIGH COOLANT TEMP

4

CHG ALT

3

FLEXIBLE IF

J1939 IN USE

LOW OIL PRESSURE

2

EMERGENCY STOP

1

FUEL (FLEXIBLE)

CRANK

O/P B

FUEL

O/P A

+VE

-VE

BATTERY

40

MAINS

DSE NET

LOADING

HIGH SPEED

RELAY(7320)

PERIPHERAL LINK

OUTPUT C

(ALL MODELS)

GENERATOR

LOADING RELAY

OUTPUT D

GEN VOLTS

FLEXIBLE IF

J1939 IN USE

B

39

+ -

A

SCR

42

H

41

USER CONFIGURABLE +VE OUTPUT H