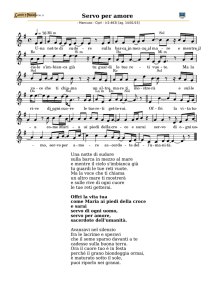

servo sistemi AC serie EDB/EDC

AC servo systems EDB/EDC series

Servo Drive Serie EDB/EDC

EDB/EDC Series Servo Drive

Nuova gamma di servo sistemi con

controllo full-digital. Semplici nell'uso e nella configurazione, con

caratteristiche dinamiche elevate,

la serie EDB/EDC è adatta alla maggior parte delle applicazioni di automazione industriale.

La serie EDB prevede il controllo di

velocità, di coppia e di posizione

(anche con ingresso analogico). La

serie EDC prevede il solo controllo

di posizione (non ingressi analogici).

New servo system product range

with full-digital control. Easy to use

and configure, with high dynamic

features, EDB/EDC series is suited to most of industrial automation applications.

EDB series is foreseen with control speed, torque and position

(also with analog input). EDC series

is foreseen the only with position

control (no analog inputs).

SPECIFICHE GENERALI | GENERAL SPECIFICATIONS

EDC –

Modello EDC

EDC Model Servo Drive

08

A

P

E

Potenza nominale

Rated Output Power

Tensione alimentazione

Power Voltage

Tipo controllo

Control Style

Versione

Designing Sequence

codice

sign

significato

specification

codice

sign

significato

specification

02

04

200 W

400 W

A

230 VAC

EDB –

Modello EDB

EDB Model Servo Drive

codice

sign

significato

specification

codice

sign

significato

specification

P Controllo di Posizione

Position Control

E

Versione

Designing Sequence

10

A

M

A

Potenza nominale

Rated Output Power

Tensione alimentazione

Power Voltage

Tipo controllo

Control Style

Versione

Designing Sequence

codice

sign

significato

specification

02

04

08

10

15

20

0.2

0.4

0.75

1.0

1.5

2.0

kW

kW

kW

kW

kW

kW

codice

sign

significato

specification

codice

sign

significato

specification

codice

sign

significato

specification

A

230 VAC

M

Controllo di Velocità,

Coppia e Posizione

Speed, Torque and

Position Control

A, B

Versione

Designing

Sequence

TABELLA ABBINAMENTI | MODEL COMPARISON TABLE

servomotori / servo motors

serie

potenza

series

power

bassa inerzia

small inertia

servoazionamento / servo drive

monofase

trifase

single phase

three phase

200 W

EMJ-02APA■

■ ■ EDC-02A■

■ ■ EDB-02A■

■■

EDB-02A■

■■

EMJ

400 W

EMJ-04APA■

■ ■ EDC-04A■

■ ■ EDB-04A■

■■

EDB-04A■

■■

3000 min-1

750 W

EMJ-08APA■

■■

EDB-08A■

■■

EDB-08A■

■■

1000 W

EMJ-10APA■

■■

EDB-10A■

■■

EDB-10A■

■■

1.0 kW

EMG-10APA■

■■

EDB-10A■

■■

EDB-10A■

■■

1.5 kW

EMG-15APA■

■■

EDB-15A■

■A

EDB-15A■

■A

2.0 kW

EMG-20APA■

■■

EMG

media inerzia

-1

medium inertia 2000 min

2 | EDB/EDC

modello

model

EDB-20A■

■A

applicazioni / application

Macchine SMT

Surface Mounting Machine

Punzonatrici PCB

PCB Puncher Machine

Bracci Robot / Robot Arm

Manipolatori / Handling Machinery

Macchine Alimentari

Foodstuff Processing Machinery

Macchine Tessili / Textile Machinery

Macchine Utensili / Machine Tools

Manipolatori / Handling Machinery

Macchine Alimentari

Foodstuff Processing Machinery

Macchine Tessili / Textile Machinery

SPECIFICHE TECNICHE SERVOAZIONAMENTI

TECHNICAL SPECIFICATION AND MODEL OF SERVO DRIVES

modello servoazionamento / servo drive model

serie EDB / EDB series

serie EDC / EDC series

mono e trifase AC230V+10-15%, 50/60Hz

single/three phase AC230V+10-15%, 50/60Hz

monofase AC230V+10-15%, 50/60Hz

single phase AC230V+10-15%, 50/60Hz

SVPWM

SVPWM

encoder incrementale

2500P/R 8 fili

8 cores (wire-saving) incremental type

encoder (2500P/R)

encodere incrementale

2500P/R 8 fili

8 cores (wire-saving) incremental type

encoder (2500P/R)

temperatura lavoro / stoccaggio

operating / storage temperature

0~55°C / -20~85°C

0~55°C / -20~85°C

umidità lavoro / stoccaggio

operating / storage humidity

inferiore 90% (senza condensa)

below 90% RH (non-condensing)

inferiore 90% (senza condensa)

below 90% RH (non-condensing)

resistenza urti o vibrazioni

shock / vibration resistance

4.9 m/s2 / 19.6 m/s2

4.9 m/s2 / 19.6 m/s2

a pannello / base mounted

a pannello / base mounted

1:5000

1:5000

in funzione a carico

load regulation

0~100%: sotto 0.01% (alla vel. nom.)

0~100%: below 0.01% (at rated speed)

0~100%: sotto 0.01% (alla vel. nom.)

0~100%: below 0.01% (at rated speed)

in funzione tensione

voltage regulation

velocità nom. ±10%: 0% (alla vel. nom.)

rated speed ±10%:0% (at rated speed)

velocità nom. ±10%: 0% (alla vel. nom.)

rated speed ±10%:0% (at rated speed)

in funzione della temperatura

temperature regulation

25±25°C: sotto 0.1% (alla vel. nom.)

25±25°C: below 0.1% (at rated speed)

0~40°C: sotto 0.1% (alla vel. nom.)

0~40°C: below 0.1% (at rated speed)

250 Hz (JL≤JM)

250 Hz (JL≤JM)

tensione alimentazione / power supply

tipo controllo / control mode

retroazione / feedback

dati di base

basic data

condizioni operative

working condition

struttura / structure

range controllo velocità / speed control range

regolazione velocità

speed regulation

risposta in frequenza / frequency characteristics

rampe accelerazione / decelerazione

deceleration / acceleration time

controllo

di velocità

speed control

mode

ingresso riferimento

velocità

speed ref. input

ingresso riferimento

di coppia

torque ref. input

controllo

di posizione

position

control mode

ingresso in

frequenza

reference pulse

0~10s

_

tensione di riferimento

reference voltage

±10V DC

–

impedenza all’ingresso

input resistance

40KΩ

–

tempo campionamento

loop time constant

47µS

–

tensione di riferimento

reference voltage

±10V DC

–

impedenza all’ingresso

input resistance

40KΩ

–

tempo campionamento

loop time constant

47µS

–

tipo frequenza

type

Frequenza + segno, A/B, CCW+CW

treno di impulsi

SIGN+PULSE train, sin. Pulse phase A

and phase B, CCW+CW Pulse train

Frequenza + segno, A/B, CCW+CW

treno di impulsi

SIGN+PULSE train, sin. Pulse phase A

and phase B, CCW+CW Pulse train

tipo segnale

pulse buffer

line driver +5V. Open collector

line driving (+5V level). Open collector

line driver +5V. Open collector

line driving (+5V level). Open collector

frequenza ingresso

pulse frequency

max 500 Kpps (differenziale) /

200 Kpps (open collector)

maxi 500 Kpps (difference) / 200 Kpps

(open collector)

max 500 Kpps (differenziale) /

200 Kpps (open collector)

maxi 500 Kpps (difference) / 200 Kpps

(open collector)

EDB/EDC | 3

modello servoazionamento / servo drive model

ingresso controllo / control signal

settaggio offset

offset setting

compensazione feed/forward

feed forward compensation

controllo di

posizione

position control

mode

definizione errore posizione

in position error setting

segnali in uscita

output signal

uscita posizione

position output

rapporto

dividing ratio

ingressi digitali

sequence control input

serie EDB / EDB series

serie EDC / EDC series

CLR clear

0~300r/min (con risoluzione a 1r/min)

0~300r/min (set resolution as 1r/min)

0~100% (con risoluzione a 1%)

0~100% (set resolution as 1%)

0-500 unità

(con risoluzione di 1)

0~500 reference unit (set resolution

as 1 reference unit)

segnali A, B, C

line driver

phase A, phase B and phase C:

line driving output

CLR clear

segnali A, B, C

line driver

phase A, phase B and phase C:

pine driving output

(1~2500) / 2500

(1~2500) / 2500

servo ON, proportional control or control

mode switch, forward run prohibited,

reverse run prohibited, alarm reset,

FWD torque external limit, REV torque

external limit, zero clamp signal

servo ON, alarm reset, error counter

clear signal, zero clamp signal

servo alarm, servo ready, positioning

complete (speed coincidence),

brake release, limiting torque,

motor run detection

servo alarm, positioning complete

(speed coincidence), brake release,

limiting torque

RS485 - Modbus

RS232 - Modbus

CAN DS402

display 7 segmenti

e tastiera 4 tasti

five 7-segment and

4 pushbuttons (digital operation panel)

tastierino operatore opzionale

optional handheld operator

frenatura dinamica

con resistenza integrata

dynamic brake with built in regenerative

resistance

frenatura dinamica

dynamic brake

–

–

–

segnali I/O

I/O signals

uscite digitali

sequence control output

porte COM

COM function

display e tastiera

display and key pad

frenatura

braking

funzioni incluse

built-in function

protezioni

protection

altro

other

4 | EDB/EDC

sovracorrente, sovraccarico,

sovra/sotto tensione,

sovravelocità, errore encoder,

errore parametri etc.

overcurrent, overload, overspeed, under

voltage, overvoltage, encoder error,

parameter error, etc.

posizionatore 16 quote

zero clamp (with 16 internal position

nodes)

errore stadio di potenza, sovraccarico,

sovravelocità, errore tensione,

errore posizione/conteggio,

errore encoder, errore parametri etc.

IPM power module error, overload,

overspeed, voltage error, position error

counter overflow, encoder disconnected,

parameter damaged, etc.

–

Dimensioni drive EDB/EDC

EDB/EDC mounting dimension of drives

DIMENSIONI EDC | MOUNTING DIMENSION OF EDC SERVO DRIVES

DIMENSIONI EDB | MOUNTING DIMENSION OF EDB SERVO DRIVES

modello / model

EDB-08A■

■ A, EDB-10A■

■ A, EDB-15A■

■A

EDB-20A■

■A

L

185

207

W

85

123

H

187.5

270.5

S

75

75

e

75

111

f

177.5

258.5

EDB/EDC | 5

d

5

6

Connessioni tipiche EDB/EDC

EDB/EDC typical connection example

CONNESSIONI TIPICHE EDC | TYPICAL CONNECTION EXAMPLE OF EDC SERVO

Non-fuse circuit breaker

R

T

Single Phase

50/60 Hz

200~230VAC +10% -15%

Surge protector

1 Ry

Noise filter

Power OFF

Power ON

1 Ry

1 KM

1PL (Servo alarm display)

1 KM

1SUP

Motor

U

1 MC

1 MC

R

V

T

W

M

PG

EDC Servo

Drives

P

N

Encoder

2CN

PG

Regenerative Unit

Please handle shielded wires' ends properly.

1CN

PULS

P

PULS

/PULS

11

8

150

12

PAO

18

/PAO

9

PBO

Position reference

SIGN

P

SIGN

/SIGN

PL

13

150

19

/PBO

10

PCO

20

/PCO

PG Frequency Dividing Output

14

2K

1

Pin output can be defined as follows:

3

COIN: Positioning complete

(ON when positioning complete)

Servo ON:

(When ON,servo function is enable)

24VIN

BR:

16

(ON when brake is released)

S-ON

15

3.3K

CLT: Limiting Torque Output

(ON when torque goes over limiting torque)

Alarm Reset:

ALM-RST

(When ON, alarm is reset)

6

2

S-RDY: Servo Ready Output

(ON when servo is ready)

Clear signal input

(When ON, displacement is cleared)

Zero Position signal

CLR

ZPS

(When ON, search for zero position)

+24V

7

17

P

6 | EDB/EDC

ALM

5

/ALM

0V

Alarm Output:

OFF when alarm is triggered

Connector Frame

Represents multi-twisted pair shielded wires

4

FG

Shield wires are connected

to the Connector Frame

Photo Coupler Output:

Maximum voltage DC30V

Maximum current DC50mA

CONNESSIONI TIPICHE EDB | TYPICAL CONNECTION EXAMPLE OF EDB SERVO

Non-fuse circuit breaker

L1

L2

L3

Single/Three Phase

50/60 Hz

200~230VAC +10% -15%

Surge protector

1 Ry

Noise filter

Power OFF

1PL ( Servo alarm display)

Power ON

1 KM

1 KM

1 Ry

1SUP

1 MC

B1

B2

B3

L1

Motor

U

L2

M

V

L3

1★

W

2★

★

EDB Servo Drives

Encoder

L1 C

L2C

PG

2CN

Please handle shielded wires' ends properly.

1CN

Torque reference

(±10V/Rated speed)

P

V-REF

GND

T-REF

P

Speed reference

(±10V/Rated speed)

GND

PULS

P

PULS

/PULS

Position reference

SIGN

P

SIGN

/SIGN

19

LPF

20

21

34

PAO

35

/PAO

32

PBO

33

/PBO

A/D

LPF

PG Frequency Dividing Output

22

23

2K

30

PCO

25

150

31

/PCO

2K

36

18

SG

28

27

150

24

Pin output can be defined as follows:

8

26

/V-CMP+: Speed coincidence output

7

(/COIN+: ON,when speed coincident)

/V-CMP-: Positioning complete

+24VIN

Servo ON:

(When ON,servo function is enable)

/S-ON

9

10

(/COIN-: ON, when positioning complete)

2

3.3K

P control:

(When ON, P control encabled)

Forward rotation prohibited:

(When ON, forward rotation prohibited)

Reverse rotation prohibited:

(When ON, reverse rotation prohibited)

Alam reset:

(When ON, alarm reset)

Clear signal input:

When ON, displacement clear)

Forward external torque limit:

(When ON, limit enabled)

Reverse external torque limit:

/P-CON

11

12

6

N-OT

13

5

/CLT+: Torque limit output

(/CLT-: ON, when value exceeds setting)

/BR+: Break interlock output

(/BR-: ON, when break is released)

+24V

14

/CLR

15

/PCL

16

/NCL

17

Connector Frame

ALM+

3

ALM-

0V

Photo Coupler Output:

Maximum voltage DC30V

Maximum current DC50mA

FG

Shield wires are connected

to the Connector Frame

Represents multi-twisted pair shielded wires

★ Note: For EDB-08/10/15, there are no terminals: B3,

4

Alarm Output:

OFF when alarm is triggered

(When ON, limit enabled)

P

/S-RDY+: Servo ready output

(/S-RDY-: ON, when servo is ready)

P-OT

/ALM-RST

/TGON+: TGON output

(/TGON-: ON, when value exceeds

1

1,

2,

, no need of any connection.

EDB/EDC | 7

Servomotori serie EMJ

EMJ Model Servo Motor

CARATTERISTICHE

FEATURES

> bassa inerzia

> picco di coppia 300% della

coppia nominale

> disponibile con freno

> velocità massima 4500 rpm

> equipaggiato con encoder

incrementale 2500P/R

> IP65 standard

> small inertia

> peak torque up to 300%

of rated torque

> available with brake

> run at speed of up to 4500r/min

> equipped with wire-saving

encoder (2500P/R)

> standard configuration is IP65

SPECIFICHE GENERALI | GENERAL SPECIFICATION

EMJ – 08

Servomotore

Modello EMJ

EMJ Model

Servo Motor

Potenza

nominale

Rated Output

Power

codice

sign

02

04

08

10

A

P

A

1

1

Tensione

Drive

Power Voltage

Encoder

Encoder

Versione

Designing

Sequence

Tipo albero

Shaft End

Opzioni

Option Parts

significato codice

spec.

sign

200

400

750

1000

W

W

W

W

significato codice

spec.

sign

A

230 VAC

P

significato codice

spec. sign

encoder

incrementale

2500P/R

incremental

wire-saving

type:

2500P/R

A

significato codice

spec.

sign

versione

designing

sequence

significato codice

spec.

sign

1 liscio, senza

chiavetta

flat, without

keys (standard)

2 con chiavetta

e vite

in testa

flat, with keys,

with screw

thread

1

nessuno

none

2 con paraolio

with oil seal

3

con freno

(DC24V)

with brake

(DC24V)

4 con paraolio

e freno

(DC24V)

with oil seal,

with brake

(DC24V)

DIAGRAMMI COPPIA-VELOCITA’ | TORQUE-SPEED FEATURE

A

B

A: continuous working area

8 | EDB/EDC

A

B: repeatedly working area

B

A

B

A

significato

spec.

B

tensione alimentazione drive / voltage

modello servomotore

servo motor model

EMJpotenza nominale

rated output power

W

coppia nominale

rated torque

N.m

coppia picco

instantaneous peak torque

N.m

corrente nominale

rated current

Arms

corrente di picco

instantaneous max current

Arms

velocità nominale

rated speed

r/min

velocità massima

max. speed

r/min

inerzia

rotor moment of inertia X10-4kg·m2

tensione alim. freno

brake rated voltage

potenza alim. freno

brake rated power

W

coppia stazionamento freno

brake holding torque

N.m

encoder

encoder

standard

classe isolamento

insulation class

temperatura operativa

ambient temperature

umidità operativa

ambient humidity

vibrazioni

vibration

0.19 (0.23)

08APA■

■■

750

2.39

7.16

4.0

12.0

10APA■

■■

1000

3.18

9.55

5.3

15.9

1.35 (1.47)

1.74 (1.87)

7.2

11.5

1.3

3.2

encoder incrementale: 2500P/R / incremental encoder: 2500P/R

F

da 0 a +40°C (senza umidità) / 0 to +40°C (no freezing)

da 20 a 80% (senza condensa) / 20 to 80% RH (non-condensing)

49 m/s2

IP65, totalmente chiuso (esclusi cavi e connettori)

totally enclosed, self-cooled, IP65 (except for shaft opening and connectors)

enclosure

protezione

230VAC

04APA■

■■

400

1.27

3.82

2.7

8.1

3000

4500

0.31 (0.35)

DC24V±10%

02APA■

■■

200

0.64

1.91

1.3

3.9

Nota - I valori in parentesi si riferiscono alla versione con freno.

Notes - The values in parentheses are for servo motors with holding brakes.

DIMENSIONI | DIMENSION

modello

EMJ

model

EMJ

02APA■

■■

04APA■

■■

08APA■

■■

10APA■

■■

L

153(193)

183(223)

191(234)

211(254)

lato flangia / flange side

LL

123(163)

153(193)

156(199)

176(219)

LR

30

30

35

35

LE

3

3

3

3

LF

6

6

9

9

LC

60

60

80

80

LA

70

70

90

90

S

LB

50

50

70

70

LZ

5.5

5.5

6

6

14

14

19

19

tapxdepth

M5x10L

M5x10L

M6x15L

M6x15L

QK

16

16

22

22

QL

4

4

4

4

key

W

5

5

6

6

T

5

5

6

6

U

3

3

3.5

3.5

Nota - Le dimensioni in parentesi si riferiscono alla versione con freno.

Notes - The dimension in parentheses are for servo motors with holding brakes.

EDB/EDC | 9

Servomotori Serie EMG

EMG Model Servo Motor

CARATTERISTICHE

FEATURES

> media inerzia

> picco di coppia 300% della

coppia nominale

> velocità massima 3500 rpm

> equipaggiato con encoder

incrementale 2500P/R

> IP65 standard

> medium inertia

> peak torque up to 300%

of rated torque

> run at speed of up to 3500r/min

> equipped with wire-saving

encoder (2500P/R)

> standard configuration is IP65

SPECIFICHE GENERALI | GENERAL SPECIFICATION

EMG – 10

Servomotore

Modello EMG

EMG Model

Servo Motor

Potenza

nominale

Rated Output

Power

codice

sign

10

15

20

A

P

A

1

1

Tensione

Drive

Power Voltage

Encoder

Encoder

Versione

Designing

Sequence

Tipo albero

Shaft End

Opzioni

Option Parts

significato codice

spec.

sign

1.0 kW

1.5 kW

2.0 kW

significato codice

spec.

sign

A

230 VAC

P

significato codice

spec.

sign

encoder

incrementale

2500P/R

incremental

wire-saving

type:

2500P/R

significato codice

spec.

sign

A

versione

designing

sequence

DIAGRAMMI COPPIA-VELOCITA’ | TORQUE-SPEED FEATURE

A

A: continuous working area

10 | EDB/EDC

A

B

B: repeatedly working area

B

A

B

1

significato codice

spec.

sign

liscio senza

chiavetta

flat, without

keys (standard)

2 con chiavetta

e vite

in testa

flat, with keys,

with screw

thread

1

2

3

4

significato

spec.

nessuno

none

con paraolio

with oil seal

con freno

(DC24V)

with brake

(DC24V)

con paraolio

e freno

(DC24V)

with oil seal,

with brake

(DC24V)

tensione alimentazione drive / voltage

modello servomotore

servo motor model

EMGpotenza nominale

rated output power

kW

coppia nominale

rated torque

N.m

coppia picco

instantaneous peak torque

N.m

corrente nominale

rated current

Arms

corrente di picco

instantaneous max current

Arms

velocità nominale

rated speed

r/min

velocità massima

max. speed

r/min

inerzia

rotor moment of inertia X10-4kg·m2

tensione alim. freno

brake rated voltage

potenza alim. freno

brake rated power

W

coppia stazionamento freno

brake holding torque

N.m

encoder

encoder

standard

classe isolamento

insulation class

temperatura operativa

ambient temperature

umidità operativa

ambient humidity

vibrazioni

vibration

protezione

230VAC

15APA■

■■

20APA■

■■

1.5

2.0

7.16

9.55

21.5

28.7

9.0

12.0

27.0

36.0

2000

3000

10.0 (10.6)

14.5 (15.1)

19.0 (19.6)

DC24V±10%

19

10

encoder incrementale: 2500 P/R / incremental encoder: 2500P/R

F

da 0 a +40°C (senza umidità) / 0 to +40°C (no freezing)

da 20 a 80% (senza condensa) / 20 to 80% RH (non-condensing)

24.5 m/s2

IP65, totalmente chiuso (esclusi cavi e connettori)

totally enclosed, self-cooled, IP65 (except for shaft opening and connectors)

10APA■

■■

1.0

4.78

14.3

6.0

18.0

enclosure

Nota - I valori in parentesi si riferiscono alla versione con freno.

Notes - The values in parentheses are for servo motors with holding brakes.

DIMENSIONI | DIMENSION

modello

EMG

L

LL KB1

KB2 KL1

model

EMG

10APA■

■ ■ 215(269.5) 160(214.5) 84 135(189.5) 118

15APA■

■ ■ 240(294.5) 185(239.5) 109 160(214.5) 118

20APA■

■ ■ 265(319.5) 210(264.5) 134 185(239.5) 118

lato flangia / flange side

KL2

79

79

79

LR

55

55

55

LE

4

4

4

LF

LC

LA

LB

12 130 145 110

12 130 145 110

12 130 145 110

S

LZ

9

9

9

22

22

22

tapxdepth

M6x20L

M6x20L

M6x20L

QK

40

40

40

QL

5

5

5

key

W

8

8

8

T

7

7

7

U

4

4

4

Nota - Le dimensioni in parentesi si riferiscono alla versione con freno.

Notes - The dimension in parentheses are for servo motors with holding brakes.

EDB/EDC | 11

MAGNETIC PRODUCT RANGE

TORQUE MOTORS

ASYNCHRONOUS VECTORIAL

SERVOMOTORS

BRUSHLESS SERVOMOTORS

D.C. MOTORS

MAGNETIC

S.p.A.

via del Lavoro, 7

I-36054 Montebello Vicentino (VI)

tel. +39 0444 649399

fax +39 0444 440495

www.magnetic.it

[email protected]

I00260/0 - 09/2010