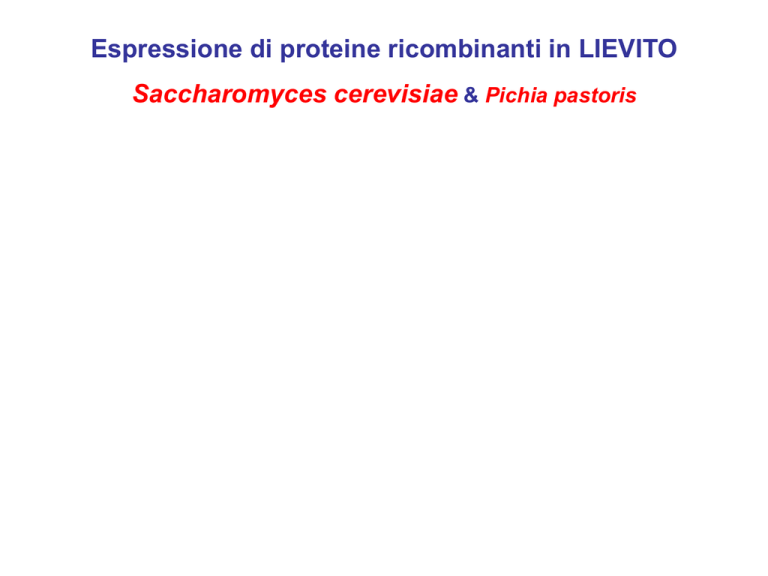

Espressione di proteine ricombinanti in LIEVITO

Saccharomyces cerevisiae & Pichia pastoris

Espressione di proteine ricombinanti in LIEVITO

Saccharomyces cerevisiae & Pichia pastoris

Vantaggi del sistema

ü Sono microorganismi eucariotici, evolutivamente più vicini ad organismi

complessi.

ü La loro coltivazione in laboratorio è semplice e relativamente economica

(assai simile a quella di cellule batteriche).

ü E’ possibile applicare svariate tecniche di ingegneria genetica,

sfruttando l’elevata capacità di ricombinazione omologa (gene

replacement).

ü Saccharomyces cerevisiae è un organismo modello, molto studiato in

termini genomici e proteomici, del quale si conoscono numerosi

meccanismi a livello molecolare.

Quali sono le caratteristiche di Saccharomyces cerevisiae?

•

Organismo GRAS (Generally Recognized As Safe)

•

Genetica e fisiologia estremamente ben conosciute

•

Cellule isolabili singolarmente e facilmente coltivabili

•

Ciclo cellulare sia aploide che diploide

•

Metabolismo sia aerobio che anaerobio

•

Isolati e sequenziati diversi promotori forti, nonché un plasmidio naturale (2 mm)

•

Cellule trasformabili

•

Secrezione di proteine minima

•

Strumento per l’analisi di geni eterologhi

•

Ridotta complessità genetica

→ Genoma completamente sequenziato

→ Progetto per l’attribuzione di una funzione alle orphan ORFs

1) preparazione protoplasti, via chimica o enzimatica

2) trattamento con LiAc

3) elettroporazione

cell

lag

log

st

La sua crescita ha un profilo tipico

t

Le condizioni nutrizionali influenzano la crescita del lievito (andamento della curva,

sporulazione)

I terreni di crescita possono essere solidi o liquidi e contengono sali minerali, vitamine, una

fonte di azoto e una di carbonio.

Si utilizzano terreni completi e terreni selettivi; esistono infatti numerosi marcatori nutrizionali

(e molti composti specifici) che permettono di selezionare i ceppi ingegnerizzati.

Inoltre, la fonte di carbonio utilizzata nella coltivazione del lievito determina l’attivazione di

percorsi metabolici specifici.

Esistono fonti di carbonio FERMENTABILI (Glucosio, Galattosio) e RESPIRABILI (Glicerolo,

Lattato, Etanolo).

COLTIVAZIONE DEL LIEVITO S. cerevisiae

Galattosio

Glucosio

Etanolo Glicerolo

Lattato

Glicolisi

Piruvato

FERMENTAZIONE

Etanolo

RESPIRAZIONE

Ciclo di Krebs

Bath & Murthy, Molecular Microbiology (2001), 40, p.1059

Nel 1948 (!) venne descritto per la prima volta un mutante incapace di fermentare il

galattosio alla stessa velocità del wild-type.

Long-Term Adaptation

GAL3 è espresso a livello basale in glicerolo, indotto 3-5 volte all’aggiunta di

galattosio, strettamente represso in presenza di glucosio.

Regolazione dipendente dalla fonte di carbonio

I geni GAL per il metabolismo del Galattosio sono organizzati in un

regolone e sono controllati a livello trascrizionale dalla fonte di carbonio

Gal3

Co-inducer/CYTOPLASM

repressor

DNA-binding transcriptional

activator

I geni GAL per il metabolismo del Galattosio subiscono una regolazione

trascrizionale duplice: repressione/derepressione e induzione

Glicerolo

Glucosio (± Gal)

Galattosio

Trascrizione geni GAL

L’aggiunta di galattosio fa aumentare di un fattore 1000 la trascrizione del

messaggero, fino a raggiungere l’1% degli mRNA totali → un potente e preciso

interruttore molecolare.

Elementi che hanno reso possibile l’ingegnerizzazione del lievito:

• isolamento di promotori regolabili (GAL1, PGK glucosio, CUP1 rame);

• isolamento di origini di replicazione → plasmide naturale 2µ, ARS;

• identificazione di markers di selezione → auxotrofie;

• possibilità di ottenere facilmente mutazioni condizionali

→ mutanti termosensibili “ts”;

• elevata frequenza di ricombinazione omologa.

Vettori utilizzabili in lievito

• plasmidi integrativi

YIp

• plasmidi replicativi

YEp

YRp

YCp

• cromosomi artificiali

YAC

… e ingegnerizzabili in E.coli, perché vettori navetta

Elementi che hanno reso possibile l’ingegnerizzazione del lievito:

• isolamento di promotori regolabili (GAL1, PGK glucosio, CUP1 rame);

• isolamento di origini di replicazione → plasmide naturale 2µ, ARS;

• identificazione di markers di selezione → auxotrofie;

• possibilità di ottenere facilmente mutazioni condizionali

→ mutanti termosensibili “ts”;

• elevata frequenza di ricombinazione omologa.

Marcatori di selezione:

come sono stati originariamente isolati?

Per complementazione in E.coli.

Transform Leu- E.coli

Plate onto medium lacking leucine

Marcatori di selezione usati più frequentemente

Elementi che hanno reso possibile l’ingegnerizzazione del lievito:

• isolamento di promotori regolabili (GAL1, PGK glucosio, CUP1 rame);

• isolamento di origini di replicazione → plasmide naturale 2µ, ARS;

• identificazione di markers di selezione → auxotrofie;

• possibilità di ottenere facilmente mutazioni condizionali

→ mutanti termosensibili “ts”;

• elevata frequenza di ricombinazione omologa.

“Gene targeting” mediante ricombinazione omologa

Knock-Out del gene URA3

Knock-Out del gene YFG

(knock-in del gene YFG)

(knock-in del gene URA3)

Left segment

of URA3

URA3::YFG

Right

segment of

URA3

Left

segment of

YFG

Right segment

of YFG

YFG::URA3

ESPRESSIONE DI PROTEINE RICOMBINANTI IN Saccharomyces

cerevisiae MEDIANTE SISTEMI GAL

Ponendo una sequenza

codificante sotto il controllo del

promotore GAL1, la sua

trascrizione viene fortemente

indotta in terreno contenente

Galattosio e può essere

immediatamente repressa in

presenza di Glucosio

Ciò permette un controllo

dell’espressione basato sulla

variazione delle condizioni di

crescita

Nel 1984 viene prodotto in lievito il primo vaccino ricombinante costituito da una subunità del capside del

virusdell’epatite B. I tentativi di produrlo in E. coli erano precedentemente falliti.

La proteina ricombinante è assai simile a quella naturale

e conserva anche la capacità di formare aggregati

immunogenici simili a quelli trovati in pazienti infetti.

…

…

Proteine ricombinanti

prodotte in S. cerevisiae

Problemi possibili per

l’espressione in questo sistema:

• perdita del plasmide

• iperglicosilazione di alcune

proteine (v. oltre)

• secrezione di proteine limitata

Improved production strains of yeast S.cerevisiae…

Altering the membrane lipid content …

Pichia pastoris

TASSO NO MIA: Euka ryota , Fung i, Asc o m yc ota , Sa c c ha rom yc o tina ,

Sa c c ha rom yc e te s,Sa c c ha ro m yc e ta le s, Sa c c ha rom yc e ta c e a e , Pic hia

Why is Pichia pastoris advantageous for industrial applications?

•

simplicity of the techniques

•

capacity to produce large (intra- or extra-cellular) quantities of protein

• possibility of post-translational modifications

• various commercialized systems

• easy to move from the lab- to the fermenter-scale

Expression of recombinant proteins in Pichia pastoris

P.pastoris is a yeast capable of expressing the recombinant protein at levels

10-100 times higher than in S. cerevisiae.

Its hyper-glycosilation activity is lower than that of S.cerevisiae and

thus its secretory properties are greater.

Some of the genetic engineering strategies used in S.cerevisiae are

similar to those employable with Pichia.

Sequencing of the genome completed and published, although relatively

late with respect to other species

(

).

Pichia pastoris is a methylotrophic yeast, capable of using methanol as the sole

carbon source.

Protein-coding genes were automatically

predicted using EuGene15... manually

curated for functional annotation,

accurate translational start-and-stop

assignment, and intron location.

This resulted in a 5,313 protein-coding

gene set of which 3,997 (75.2%) have at

least one homolog in the National Center

for Biotechnology Information protein

database.

The protein-coding genes occupy 80% of

the genome sequence.

To be used, the methanol must first be oxidized to formaldehyde in

peroxisomes by the enzyme alcohol oxidase.

METANOLO

O2

alcohol oxidase

FORMALDEIDE

H2O2

alcohol oxidase has low affinity for O2 and, when growing in methanol, the

yeast cell increases the production of the enzyme.

Pichia has two alcohol oxidase genes (AOX1, AOX2): AOX1 supports most

of the enzymatic cellular activity.

In Pichia pastoris, The gene AOX1 undergoes an adjiustement similar to that of

genes GAL in S.cerevisiae: repression / derepression and induction.

Glycerol

Glucose (± Methanol)

Methanolo

Transcription of gene AOX1

In methanol, the AOX1 protein represents about 30% of the soluble protein

and its mRNA 5% of the cell messengers.

The regulation of the AOX1 gene is therefore used for the production of

recombinant proteins in Pichia pastoris.

The loss of the gene AOX1 (MutS) confers to the cell a

distinctive phenotype, i.e. growth slowed in methanol.

Vectors

Promoters

– AOX1 (alcohol oxidase)

• Strong promoter

• Strongly inducible by methanol

• Repressed by D-glucose

– GAP (glyceraldehyde 3-phospate

dehydrogenase)

• Strong constitutive promoter

• High transcription in D-glucose,

• Moderate transcription in glycerol

• Low transcription in methanol

Markers

ARG4, URA3, HIS4, Sh ble (gene from Streptoalloteicus hindustanus)

Secretion signals

α-MF (S.cerevisiae mating factor a), PHO1 (P.pastoris acid phosphatase)

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

INTRACELLULAR

system

SECRETION

system

recombinant protein with epitopes 6XHis

and c-myc at the C-terminal

Pichia secretes few native proteins, so that the

recombinant one can represent the most abundant

specie in the culture medium

In the absence of a native signal, the prepropeptide of

α-factor of S. cerevisiae is one of the most efficient

secretion signals

The peptide is removed by specific proteases prior to

secretion (Kex2, Ste13)

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

Plasmid for intracellular expression

Plasmid for secretion

Construction of the specific vector

ORF at 5’ (α-factor)

Kex2 E Ste13 sites

(removal of α-factor)

ORFs at 3’ (c-myc –

6xHis)

pPICZα-A

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

Control by sequencing of the correct insertion of the DNA fragment and

of the absence of point mutations or premature STOP codons

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

3) Engineering of Pichia pastoris

Strain transformation

A single homologous

recombination event allows the

integration of the plasmid into

the genome

The presence of the

marker Zeocin allows

selection of the

engineered strains

Expression of recombinant proteins in Pichia pastoris

The expression vectors can be cut in such a way as to allow only the

integration of the expression cassette and marker gene flanked by

sequences 5 'and 3' of the AOX1 gene, replacing the AOX1 gene

(knocked-out)

The result is a Muts phenotype that can be identified by plating the cells on

methanol → slow growth

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

3) Engineering of Pichia pastoris

4) Control analysis

analytic PCR on genomic DNA to detect possible multiple integrations

sequencing of the junction (control of integration)

Control analysis of the engineered Pichia pastoris strains

The high frequency of homologous recombination typically leads to a

high number of transformants (> 50)

The engineering can alter the function of the gene AOX1 of Pichia

(phenotype MutS).

It is therefore necessary to carry out the analysis of the phenotype of

the strains obtained (growth in methanol).

Sometimes, it is advantageous to use a MutS strain, or a strain mutated

in genes encoding proteases.

Moreover, it can be advantageous to use a strain with multiple

integrations (in this case, it is useful to use vectors with the gene

conferring resistance to kanamycin or to zeocin).

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

3) Engineering of Pichia pastoris

4) Control analysis

5) Choice of the best engineered strains

Selection of strains by growth on medium

containing methanol.

Small-scale cultures and protein analysis

of SDS / PAGE and Western blotting.

Expression of recombinant proteins in Pichia pastoris

1) Choice of the expression system

2) Construction of the specific vector

3) Engineering of Pichia pastoris

4) Contol analysis

5) Choice of the best engineered strains

6) Preparation of large scale cultures and protein purifiction

- Flasks with liquid media

- FERMENTERS (high density cultures)

• Control of nutrients

• pH

• Aeration

Simply to change the scale of production from flask to

fermenter → the yield of the protein can increase

significantly

( > 400g/l wet weight; DO600> 500u/ml )

Expression of recombinant proteins in Pichia pastoris

• High scale production in a fermenter

– The transformant selected for the fermentation is initially grown in rich

medium with glycerol as the carbon source

• accumulation of biomass

• repressed expression

– Glycerol is then added in limited amounts as long as the culture does

not reach the desired level of biomass → > cell viability, more rapid

induction, > yield of recombinant protein.

– Finally, the administration of methanol to induce the expression can

be started.

– N.B .: control [glycerol], [ethanol], [acetate].

Overall, the codon usage is similar to the one for S. cerevisiae. … The codon

optimization of the gene of interest and its eventual fusion partners often results

in higher protein expression levels.

The commonly used methanol-inducible promoters in P. pastoris—the alcohol oxidase I

promoter and the formaldehyde dehydrogenase promoter—drive the production of

enzymes needed for methanol assimilation and therefore produce extremely high levels

of these transcripts upon switching the carbon source to methanol. The genome

sequence has allowed identification of all genes coding for enzymes involved in methanol

assimilation and their promoter, which can now be studied for their suitability for

transgene expression in P. pastoris.

the results of several articles are taken under review and compared :

•

in the passage from the flask to the fermenter, the yield of recombinant

protein expressed under the control of AOX1 promoter is not always greater

than that obtainable with the GAP promoter;

•

glucose, glycerol and oleic acid, as carbon sources are substrates cheaper

than methanol and are more easily disposable;

•

you can get an increase in the yield , although significant, but not necessarily

proportional, by increasing the number of copies of the gene (eg. TNF, 20

copies of the gene → yield increased by 200 times; 19 copies of mEGF → 13 times;

8 copies of HBsAg → 11 times).

• glyco-engineered strains

NB: unfolding triggers UPR and ERAD pathways !!

More than 50% of the total proteins are glycoproteins; it is estimated that 1-2% of the

genome encodes genes involved in glycosylation or metabolism of the glycan chains

Glycosylation in cells plays a role in:

• Assumption of the correct folding

• stability of the protein

• adhesion between different cells and between identical cells (in tissues)

• internalisation of viruses

• recognition and response to external agents (NB: eg. Leukocytes expose the membrane

molecules CAM = cell adesion molecules, extensively glycosylated, which play a key role in

inflammatory and immune responses, or glycoproteins surface antigens of red blood cells AB )

N-glycosylation: the chain is covalently linked to ASP consensus Asp-X-Ser / Thr (where X

is any aa ≠ Pro)

O-glycosylation: Ser or Thr, consensus sequences not yet identified; in the Golgi

C-mannosylation: C2-alpha-mannosyltryptophan [(C2-Man-) Trp]

Phospho-glycosylation: Ser or Thr, via phosphodiester bond

Berger, Kaup and Blanchard. Protein Glycosylation and Its Impact on Biotechnology. Adv Biochem Engin/Biotechnol, vol. 127 (2012)165-185

Berger, Kaup and Blanchard. Protein Glycosylation and Its Impact on Biotechnology. Adv Biochem Engin/Biotechnol, vol. 127 (2012)165-185

Berger, Kaup and Blanchard. Protein Glycosylation and Its Impact on Biotechnology. Adv Biochem Engin/Biotechnol, vol. 127 (2012)165-185

3 Glu

9 Man

2 GlcNAc

In terms of N-glycosylation, P.

pastoris modify proteins with a

range of heterogenous high

mannose glycans, which

introduce a large amount of

heterogeneity in the protein

(reducing downstream processing

efficiency and complicating

product characterization)…

To overcome the difficulties,

strains have been developed with

an entirely re-engineered

glycosylation pathway to produce

human IgG–type N-glycans

(N-glycosylation humanization

technology).

Kim et al., Yeast synthetic biology for the production of recombinant therapeutic proteins

(2015). FEMS Yeast Research 15:1-16

Hamilton and Gerngross, Current Opinion in Biotechnology 2007, 18:387–392

Kim et al., Yeast synthetic biology for the production of recombinant therapeutic proteins

(2015). FEMS Yeast Research 15:1-16

β-1,2-N-acetylglucosaminyltransferase

mannosidase

galactosyltransferase

sialilyltransferase

S.cerevisiae

P.pastoris

ü More possibilities for genetic

manipulation

ü Higher protein yield

ü reduced margins of manipulation

ü strictly defined growth conditions

ü Very wide choice of resources and

tools (strains, vectors, growth media,

bioinformatics tools)

ü Comprehensive understanding of the

structure è almost unlimited literature

ü NB: if the expression is not simple and

immediate, process optimization can

be very laborious

ü limited literature

ü huge interest for industrial

developments

http://www.pichia.com/welcome/

For studying:

•

MOLECULAR BIOTECHNOLOGY

Glick, Pasternak, Patten – 4th edition – chapter 7

•

Ahmad, Hirz, Pichler and Schwab. Protein expression in Pichia pastoris:recent

achievements and perpectives for heterologous protein production. Appl Microbiol

Biotechnol (2014) 98: 5301-5317

Berger, Kaup and Blanchard. Protein Glycosylation and Its Impact on

Biotechnology. Adv Biochem Engin/Biotechnol, vol. 127 (2012) 165-185

•

To explore the topic:

•

•

Puxbaum, Mattanovich and Gasser. Quo vadis? The challenges of recombinant

protein folding and secretion in Pichia pastoris. Appl Microbiol Biotechnol (2015)

99:2925–2938

Spohner, Müller, Quitmann and Czermak. Expression of enzymes in food and

feed industry with Pichia pastoris. Journal of Biotechnology (2015) 202: 118-134

(in the second part of the review real examples are presented of enzymes

produced by adapting, case by case, strategies and condition for achieving overexpression)