caricato da

monkeyabc23

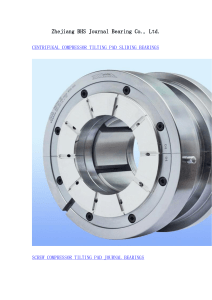

Zhejiang BHS Journal Bearing Co., Ltd Technology

Technology ZheJiang BHS Journal Bearing Co.,Ltd. has a high-quality professional team who have abilities of calculation, measurement, testing that effectively control manufacturing processes of JournalBearings ,Tilting pad bearings,thrust bearings products, establishing and perfecting quality control system and quality records. Company has all kinds of testing equipments and measuring instruments making us have abilities of ultrasonic flaw detection, dye detection, magnetic particle inspection; hardness testing capability after heat treatment; detection capability to inside diameter, outer diameter, plane, and curved face after machined, groove shaped, paint surface dry film, wet film detection capability etc. BHS bearings has Modern casting workshop and machining workshop and bearing dust-free assembly workshop. Some of the equipments are imported CNC machining center, including United States Haas, Germany DMG, Seiko of Japan and Taiwan oil Hin CNC machining center. These CNC center machines can make accuracy grade ISO-6 for tilting pad bearing. Has ability to manufacture all kinds of bearings such as dislocation tile, tilting pad, oil Yewa, multi oil gap tile. Bearing alloy raw materialmainly from Yunnan Tin Industry Co., Ltd., which can provide complete chemical composition and mechanical properties report. If there are special requirements on bearing alloy, we can direct buy from abroad. BHS bearings has professional annealing equipment, box type resistance furnace, the device can automatically record the annealing temperature curve. Our company has leading technology of casting bearing alloy and full automatic centrifugal casting equipment that according to the size and thickness of tilting to adjust the speed, cooling water, cooling time. The maximum diameter of bearing can be casting at 1.2m(diameter). Company's conventional bearing ultrasonic flaw detection meet standardISO4386-1 and conforms to standard ISO4386-1 requirements. Dye penetration test can reach the surface of the alloy casting layer should have no crack marks, and its defect group in accordance with the requirements of ISO4386-3 "sliding bearing, multilayer metal sliding bearing", and the acceptance grade A in nondestructive penetration test. Quality inspectors have certificates of PT, UT. In order to thoroughly solve the trouble of Babbitt metal segregation, our company successful development of a domestic only "bearing spraying workmanship for Babbitt alloy" after years of exploration and research and experienced thousands of times of trial and error.Characteristics of the workmanship for Bus: Babbitt alloy microstructure is uniform, fine, without pores, crystal structure into a mesh, oil rate is high, low coefficient of friction, enhance bearing temperature resistance, vibration resistance. Bearing life get much higher than domestic similar bearing casting process. ZHEJIANG BHS JOURNAL BEARING CO.,LTD. No.513 Zhu An Road,Zhu Ji city ZheJiang Province. Tel:+86-575 -87957662 Fax:+86-575-87962292 H.P:+86-13671799082 Wechat:13671799082 Whatsapp:+86 18016318890 Skype:galaxyzhangfeng www.bhsbearings.com [email protected]